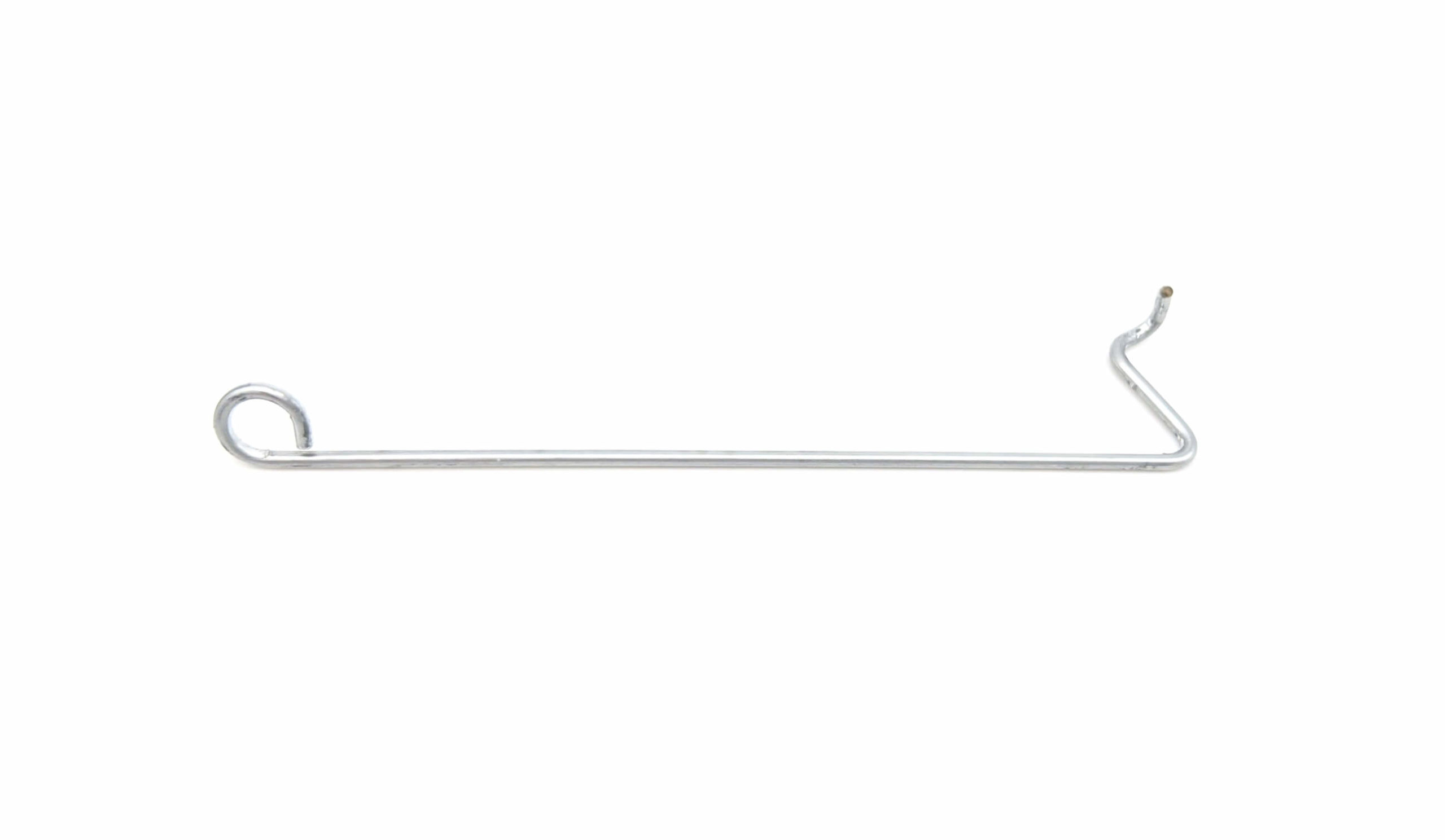

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Have you ever stopped to consider the humble coil spring? These seemingly simple devices, often hidden from view, play a vital role in countless aspects of our lives. From the

Have you ever stopped to consider the humble coil spring? These seemingly simple devices, often hidden from view, play a vital role in countless aspects of our lives. From the smooth suspension of our cars to the delicate mechanisms of our watches, coil springs are the unsung heroes that ensure our world runs smoothly. They are the silent powerhouses that store and release energy, providing stability, control, and functionality in countless applications. Let's delve into the fascinating world of coil springs, exploring their history, types, and the science behind their remarkable capabilities.

The use of springs dates back to ancient times, with simple non-coiled springs like bowstrings being employed for hunting and warfare. The Bronze Age witnessed the emergence of more sophisticated spring devices, such as tweezers, showcasing the growing understanding of elasticity and its applications. It was Ctesibius of Alexandria, a brilliant inventor, who developed a method for crafting springs from bronze alloys, using an increased proportion of tin and hardening them through hammering after casting. This advancement marked a significant step towards the coil springs we know today.

Coiled springs first appeared in the 15th century, initially used in door locks. This period also saw the invention of spring-powered clocks, which gradually evolved into the first large watches by the 16th century. This innovation revolutionized timekeeping, paving the way for the precise and reliable timepieces we rely on today.

In 1676, a landmark moment in the understanding of springs arrived with British physicist Robert Hooke's groundbreaking law. This law, known as Hooke's Law, established a fundamental relationship between the force exerted by a spring and its extension or compression. It stated that the force is directly proportional to the change in length, a principle that remains a cornerstone of spring mechanics.

Coil springs come in a wide variety of types, each tailored to specific applications. Their design depends on the forces they need to handle, the direction of those forces, and the required level of stiffness or flexibility.

Compression springs, as the name suggests, are designed to resist compression forces. When a load is applied, they shorten in length. These springs are commonly found in applications such as:

Tension springs are the opposite of compression springs; they resist tension forces and elongate when stretched. Some common uses include:

Torsion springs are designed to resist twisting forces, storing energy by rotating about their axis. Their applications often involve controlled rotation:

Beyond these basic types, there are many specialized coil springs designed for specific purposes:

The behavior of coil springs is governed by fundamental principles of physics, notably Hooke's Law, which states that the force exerted by a spring is proportional to its displacement. This means that the more you stretch or compress a spring, the greater the force it will exert in opposition to the change. This linear relationship makes coil springs incredibly predictable and reliable for a wide range of applications.

However, Hooke's Law is an approximation that holds true for small displacements. As the spring is stretched or compressed beyond a certain point, its behavior becomes more complex, and the linear relationship breaks down. This is because the material reaches its elastic limit, and further deformation can lead to permanent changes or even failure.

Coil springs are typically made from spring steel, a high-carbon alloy known for its exceptional elasticity and strength. The specific type of spring steel used depends on the intended application, as different grades offer varying levels of strength, fatigue resistance, and corrosion resistance. For instance, high-carbon steel is often used for springs requiring high strength and durability, while stainless steel is preferred for applications exposed to corrosive environments.

While steel is the dominant material for coil springs, advancements in materials science have opened doors to new possibilities. Non-ferrous metals like phosphor bronze and titanium are used for springs requiring corrosion resistance, while low-resistance beryllium copper finds application in springs carrying electrical currents. Additionally, composites and polymers are increasingly used in some applications where weight reduction, corrosion resistance, or specific elastic properties are paramount.

The humble coil spring, often overlooked, plays a critical role in numerous aspects of our lives. From the smooth ride of our cars to the delicate mechanisms of our watches, these silent powerhouses provide stability, control, and functionality across a vast spectrum of applications. As technology continues to evolve, coil springs remain an indispensable component of mechanical systems, contributing to the efficiency, precision, and safety of our modern world.

Coil springs, with their unassuming presence, are a testament to the power of simple yet fundamental principles in engineering. Their ability to store and release energy, providing stability, control, and functionality, makes them an indispensable component of countless devices and systems. As we continue to explore new materials and designs, the role of coil springs in our lives is sure to grow even more significant.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.