Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Coil spring pins, often overlooked, are essential components in countless mechanical assemblies. These seemingly simple fasteners play a crucial role in securing parts, absorbing shock, and ensuring smooth operation. From

Coil spring pins, often overlooked, are essential components in countless mechanical assemblies. These seemingly simple fasteners play a crucial role in securing parts, absorbing shock, and ensuring smooth operation. From delicate electronics to heavy-duty machinery, coil spring pins quietly perform their duty, providing reliable and efficient performance. Let's delve into the world of these resilient pins, exploring their types, applications, and the reasons why they are indispensable in modern engineering.

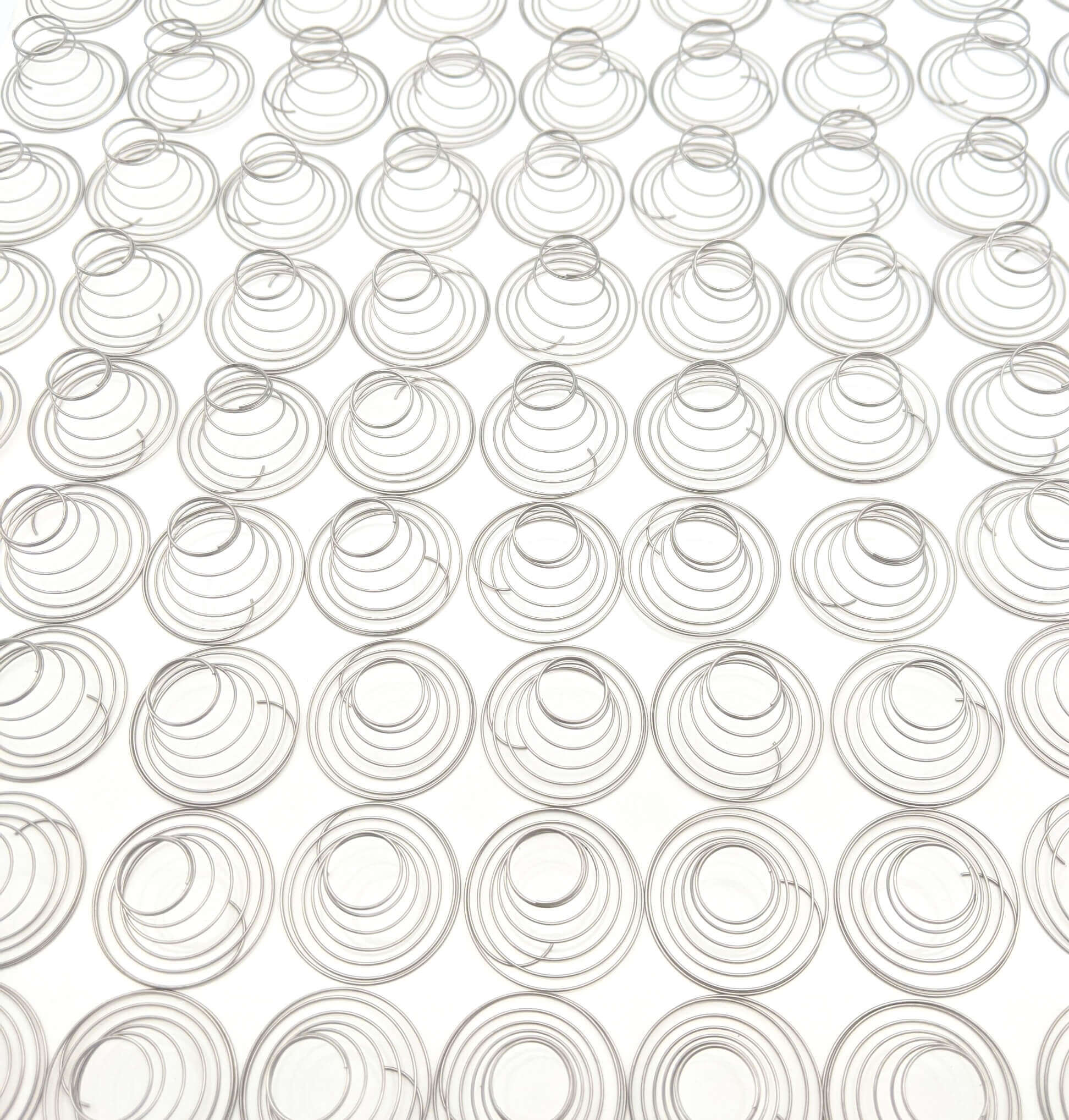

Imagine a tiny, coiled spring that is compressed to form a cylindrical pin. That's the essence of a coil spring pin, a type of fastener that combines the resilience of a spring with the practicality of a pin. They are designed to provide a snug fit within a hole, offering a reliable and repeatable clamping force. This force keeps components securely fastened, while also accommodating slight misalignments or variations in component dimensions. Think of them as miniature shock absorbers, protecting the assembly from stress and wear.

Coil spring pins come in a variety of shapes, sizes, and materials, catering to a wide range of applications. The most common types include:

The versatility of coil spring pins makes them suitable for a vast array of applications across different industries. Here are some examples:

Coil spring pins offer several advantages that contribute to their widespread use in engineering and design:

Choosing the right coil spring pin for your application requires careful consideration. Here are some important factors to keep in mind:

Coil spring pins are essential components in countless mechanical assemblies, quietly performing their duty, ensuring smooth operation and providing reliable performance. They offer a blend of strength, flexibility, and affordability, making them an ideal choice for a wide range of applications. From delicate electronics to heavy-duty machinery, coil spring pins are the unsung heroes of the mechanical world. By understanding their types, applications, and advantages, engineers and designers can leverage the benefits of these resilient fasteners to create durable, reliable, and efficient assemblies.

The next time you encounter a coil spring pin, take a moment to appreciate its humble yet critical role. These small, coiled wonders are instrumental in the success of countless machines and devices, quietly ensuring that everything runs smoothly and reliably. They are a testament to the ingenuity and innovation that drives the world of engineering. So, next time you're working on a project, remember to consider the humble coil spring pin—it might just be the key to a successful and enduring assembly.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.