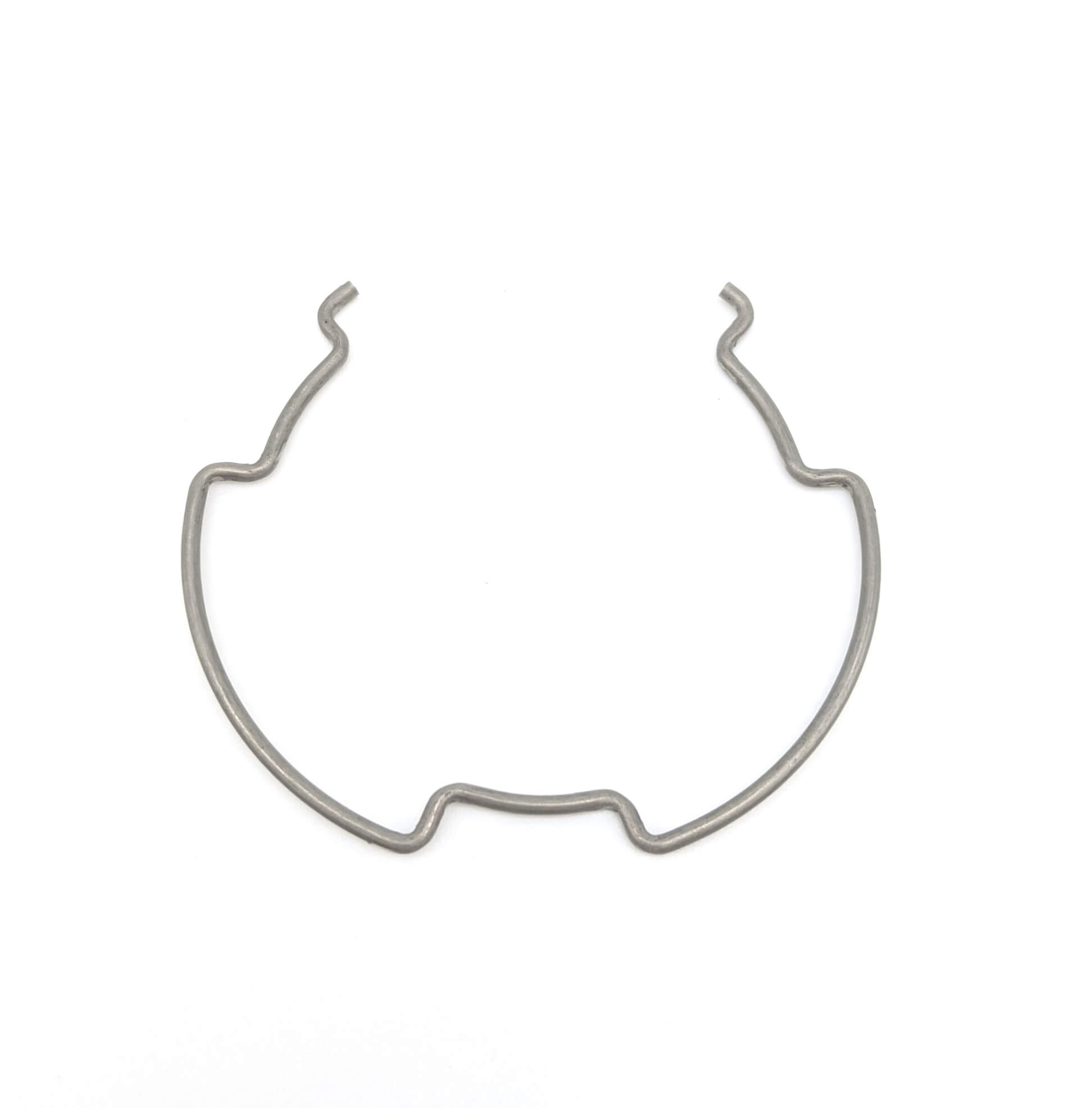

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Coil spring pins, often overlooked in the grand scheme of mechanical assemblies, play a crucial role in ensuring the smooth operation and longevity of countless machines and devices. These small,

Coil spring pins, often overlooked in the grand scheme of mechanical assemblies, play a crucial role in ensuring the smooth operation and longevity of countless machines and devices. These small, unassuming components are the backbone of many systems, quietly holding parts together, absorbing shock and vibration, and providing essential flexibility in various applications. While their size might be diminutive, their impact is significant, contributing to the reliability, efficiency, and overall performance of countless mechanical marvels.

Imagine a world without coil spring pins. It's a world where loose connections abound, where vibrations rattle and shake, and where delicate mechanisms are prone to premature wear and tear. Thankfully, we live in a world where these tiny components are ubiquitous, silently safeguarding the smooth operation of a vast array of machines and devices.

Coil spring pins, essentially cylindrical fasteners with a helical coil, are the unsung heroes of mechanical assemblies. They are the silent guardians that keep parts aligned, prevent movement, and absorb shock, contributing to the longevity and performance of countless machines. Their design allows them to be easily inserted and removed, facilitating quick assembly and disassembly, a boon for maintenance and repair.

The versatility of coil spring pins is truly remarkable. They find their place in a plethora of applications, proving their worth in diverse industries. Here are a few examples where coil spring pins shine:

Automotive: From holding suspension components to securing engine parts, coil spring pins are instrumental in ensuring a smooth and safe driving experience. Their ability to withstand harsh conditions, like temperature fluctuations and vibrations, makes them an ideal choice for automotive applications.

Aerospace: In the demanding world of aerospace, reliability is paramount. Coil spring pins, known for their strength and resilience, are employed in aircraft assemblies, ensuring the stability and safety of these complex machines that soar through the skies.

Industrial Machinery: The heavy-duty nature of industrial machinery demands robust and reliable fasteners. Coil spring pins rise to the challenge, securely holding critical components in place, enabling the efficient operation of heavy machinery in demanding environments.

Consumer Products: Don't underestimate the role of coil spring pins in everyday products. They are employed in everything from appliances like washing machines and dryers to furniture and toys, contributing to their functionality and durability.

Choosing the right coil spring pin for a particular application is crucial. Factors to consider include:

Material: The material of the coil spring pin determines its strength, resilience, and suitability for specific environments. Common materials include steel, stainless steel, and aluminum, each offering unique properties.

Size and Dimensions: The size and dimensions of the coil spring pin must match the application's requirements, ensuring a secure fit and optimal performance. The diameter and length of the pin are critical factors in this selection process.

Load Capacity: The load capacity of the coil spring pin is essential for ensuring it can withstand the forces exerted upon it. Factors like spring compression and tension are crucial in determining the appropriate load capacity.

Environment: The environment in which the coil spring pin will operate plays a significant role in material selection and design. Corrosion resistance and temperature tolerance are critical considerations for applications exposed to harsh conditions.

From the earliest days of mechanical engineering, coil spring pins have played a vital role in the evolution of technology. Their humble beginnings as simple fasteners have blossomed into a myriad of applications, contributing to the functionality, reliability, and performance of countless machines and devices. They are the unsung heroes of the mechanical world, silently safeguarding the smooth operation of our modern world.

Coil spring pins, though often overlooked, are indispensable components that hold the key to the smooth functioning of countless machines and devices. Their versatility, reliability, and contribution to the longevity of mechanical assemblies make them a crucial element in the intricate tapestry of modern engineering. Their significance cannot be understated, and their impact on our technological world is undeniable. So next time you encounter a coil spring pin, take a moment to appreciate its humble yet significant role in the grand symphony of mechanics.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.