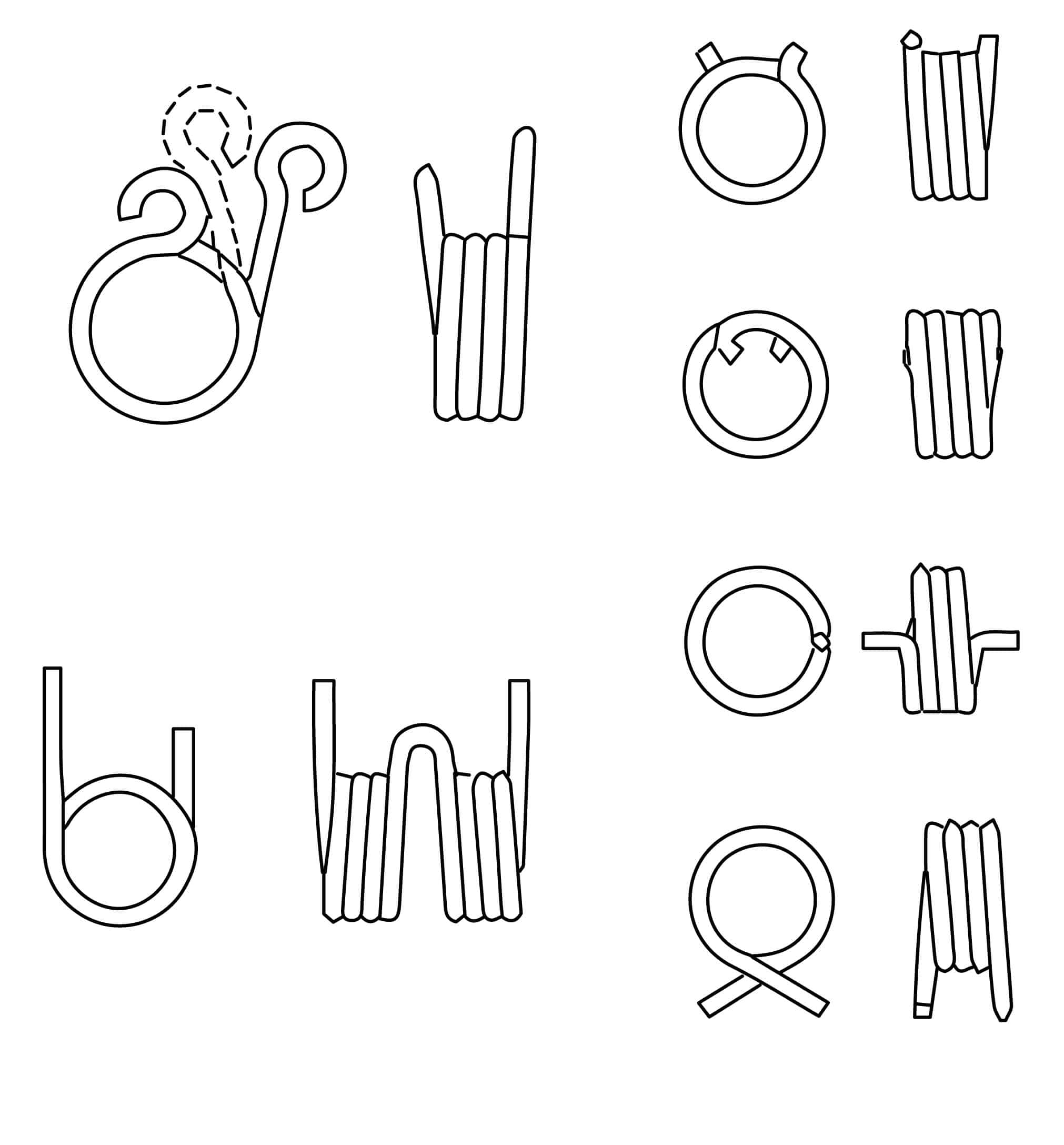

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Coil spring pins, often referred to as spring clips or spring plungers, are vital components in countless mechanical assemblies. These small but mighty fasteners provide a secure, reliable, and easily

Coil spring pins, often referred to as spring clips or spring plungers, are vital components in countless mechanical assemblies. These small but mighty fasteners provide a secure, reliable, and easily removable connection, making them indispensable in industries ranging from automotive to aerospace. Their unique design, combining a spring-loaded mechanism with a cylindrical body, allows for quick and easy assembly and disassembly, simplifying maintenance and repairs. But what exactly are coil spring pins, and how do they work?

Coil spring pins, also known as spring clips or spring plungers, are mechanical fasteners designed to provide a secure yet easily removable connection between components. They consist of a cylindrical body with a spring-loaded mechanism that allows for axial movement. The spring, typically a helical coil spring, exerts a constant force that keeps the pin in place within the mating holes. The pin is usually made of hardened steel or other durable materials, ensuring long-lasting performance.

These versatile fasteners offer several advantages that make them a popular choice in a wide range of applications:

Ease of Assembly and Disassembly: The spring-loaded mechanism makes it effortless to insert and remove coil spring pins. This feature greatly simplifies maintenance and repair tasks, allowing for quick access to components without the need for specialized tools.

Secure Connection: The spring tension provides a strong and reliable connection, ensuring that components remain securely fastened even under vibration or shock loads. This makes them suitable for applications where component stability is paramount.

Reusability: Coil spring pins are designed to be reusable. The spring mechanism allows for repeated insertion and removal without compromising the integrity of the fastener.

Variety of Sizes and Configurations: Coil spring pins are available in a wide range of sizes, materials, and configurations to suit diverse application requirements. This includes different pin diameters, spring tensions, and end designs such as ball-end, mushroom-head, and straight-end. The selection of the appropriate coil spring pin depends on the specific application and the desired level of force required to maintain the connection.

Coil spring pins come in various types, each designed to meet specific application needs. Some common types include:

Ball-End Coil Spring Pins: These pins feature a rounded, ball-shaped end that provides a smooth, consistent contact point with the mating hole. This design minimizes stress concentration at the contact point, leading to improved durability.

Mushroom-Head Coil Spring Pins: Characterized by a mushroom-shaped head, these pins offer increased holding force compared to ball-end pins. The larger head provides greater surface area for contact, enhancing the pin's resistance to displacement.

Straight-End Coil Spring Pins: These pins have a straight, unshaped end, making them suitable for applications where a specific end shape is not required. They provide a simple and economical solution for holding components together.

Coil spring pins find widespread use in countless industries and applications. Their versatility and reliability make them essential components for secure and easily removable assemblies. Some common applications include:

Automotive Industry: Coil spring pins are used in a variety of automotive components, such as door hinges, seat adjustments, and suspension systems. They provide a secure connection while allowing for easy access during maintenance.

Aerospace Industry: Due to their high strength and reliability, coil spring pins are found in aircraft components, such as control panels, landing gear, and engine mounts. They ensure the safety and integrity of these critical systems.

Electronics Industry: Coil spring pins are employed in electronic enclosures, circuit boards, and other delicate components. They provide a secure connection without damaging sensitive circuitry.

Medical Devices: In the medical industry, coil spring pins are used in medical equipment, surgical instruments, and prosthetics. Their biocompatibility and resistance to corrosion make them suitable for medical applications.

Machinery and Equipment: Coil spring pins are integral to various industrial machinery and equipment, such as pumps, compressors, and conveyors. They play a crucial role in securing components and ensuring smooth operation.

Choosing the right coil spring pin for your application involves considering several factors:

Size and Material: The pin's diameter and length should be appropriate for the mating holes and the load it needs to withstand. Material selection should be based on the operating environment and the required level of strength and corrosion resistance.

Spring Tension: The spring tension determines the holding force of the pin. It's essential to select a tension that provides sufficient force to keep the components securely fastened but not so high that it makes assembly or disassembly difficult.

End Design: The end design of the pin should be compatible with the mating holes and the application requirements. Ball-end pins are suitable for smooth contact, while mushroom-head pins provide greater holding force.

Operating Environment: Consider the operating temperature, humidity, and any corrosive substances that may be present. Choose a material and coating that can withstand these conditions.

Coil spring pins are essential components in various mechanical assemblies, offering a secure, easily removable connection that simplifies maintenance and repairs. Their versatile design, ease of use, and availability in a wide range of sizes and configurations make them a crucial fastener in industries ranging from automotive to aerospace. By carefully considering the factors discussed above, you can select the right coil spring pin to meet your specific application needs and ensure the integrity of your assemblies.

As we've seen, coil spring pins offer a robust, reliable, and user-friendly solution for countless assembly scenarios. Their adaptability and versatility make them a valuable tool for designers and engineers looking to optimize their designs and enhance the functionality and longevity of their products. If you're working on a project that requires secure, easily removable connections, consider incorporating coil spring pins into your design. You'll be thankful for their ease of use, strength, and overall contribution to a robust and efficient system.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.