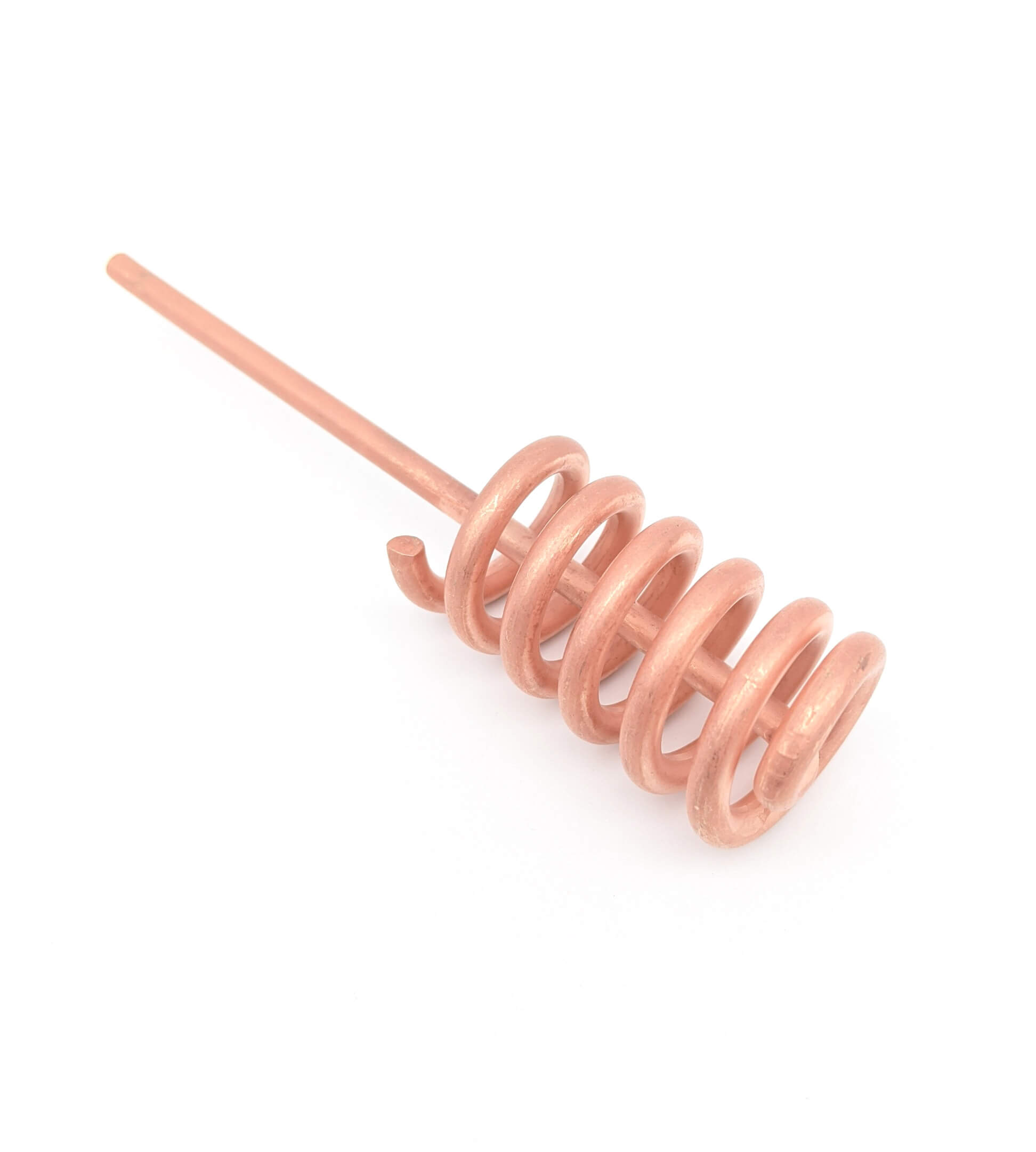

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

A coil spring compressor is an indispensable tool for anyone involved in vehicle maintenance, especially when it comes to replacing or servicing suspension components. This specialized tool allows you to

A coil spring compressor is an indispensable tool for anyone involved in vehicle maintenance, especially when it comes to replacing or servicing suspension components. This specialized tool allows you to safely compress the coil springs, making it possible to remove and install components such as struts, shocks, and control arms. But with so many different types and models available, choosing the right coil spring compressor for your needs can seem daunting. This article delves into the world of coil spring compressors, exploring their functions, types, and essential safety considerations. Let's dive in and equip ourselves with the knowledge to confidently handle those springy challenges!

Coil springs are essential components of your vehicle's suspension system, providing support and cushioning against bumps and dips in the road. When working on the suspension, it's crucial to compress the coil springs to gain access to the components attached to them. However, these springs are under considerable tension, making manual compression incredibly dangerous. This is where a coil spring compressor comes into play.

A coil spring compressor is designed to safely compress the springs, allowing technicians to work on the suspension system without risking injury. This tool essentially locks onto the spring, applying force to compress it, relieving the tension and enabling the removal and installation of other components.

The world of coil spring compressors isn't as straightforward as it seems. You'll encounter different types, each with its own advantages and disadvantages. Here's a breakdown of the most common types:

1. External Coil Spring Compressors: These compressors are the most common and utilize a set of arms that clamp onto the outside of the coil spring. The arms are then pulled together, using a hydraulic jack or a lever, to compress the spring. External compressors are generally more affordable and easier to use, making them a popular choice for DIY mechanics. However, they can be bulky and require more space for operation.

2. Internal Coil Spring Compressors: As the name suggests, internal compressors work from the inside of the coil spring. They use a threaded rod and a set of plates that are inserted into the spring. These compressors are often smaller and more compact, making them ideal for tight spaces. However, they can be more challenging to use and may require more specialized knowledge.

3. Air-Powered Coil Spring Compressors: For mechanics seeking speed and efficiency, air-powered compressors are the way to go. These utilize compressed air to power the compression mechanism, offering quick and precise operation. However, they require a reliable air source and can be more expensive.

Working with coil springs can be risky, as they hold immense potential energy. Here are some safety tips to keep in mind when using a coil spring compressor:

1. Choose the Right Compressor: Select a compressor that's specifically designed for your vehicle's coil springs. Make sure it has a sufficient capacity to handle the spring's load.

2. Proper Installation and Use: Always refer to the manufacturer's instructions for the correct installation and operation of the compressor. Make sure the compressor is securely attached to the spring before applying pressure.

3. Never Work Under a Compressed Spring: Never attempt to work under a compressed spring, as it could suddenly release, causing severe injury. Secure the spring using jack stands or other supports to ensure stability.

4. Gradual Release of Pressure: When releasing the pressure on the spring, do so gradually. Rapid release can cause the spring to bounce back unexpectedly.

Deciding on the best coil spring compressor for your needs boils down to your budget, experience, and the specific tasks you'll be tackling. If you're a DIY mechanic working on occasional repairs, an external coil spring compressor is likely a suitable choice. For professional mechanics or those working on more complex repairs, an air-powered or internal compressor might be a better investment.

A coil spring compressor is a vital tool for anyone involved in vehicle maintenance. By understanding the different types, safety precautions, and choosing the right compressor for your needs, you can safely and effectively tackle those springy challenges. Remember, prioritize safety at all times. Happy wrenching!

In the world of vehicle maintenance, a coil spring compressor is an essential tool that allows you to work safely and efficiently with suspension components. Understanding the different types, their benefits, and prioritizing safety are crucial steps for tackling those springy challenges. By following these tips and choosing the right compressor for your needs, you'll be well-equipped to maintain your vehicle's suspension system with confidence.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.