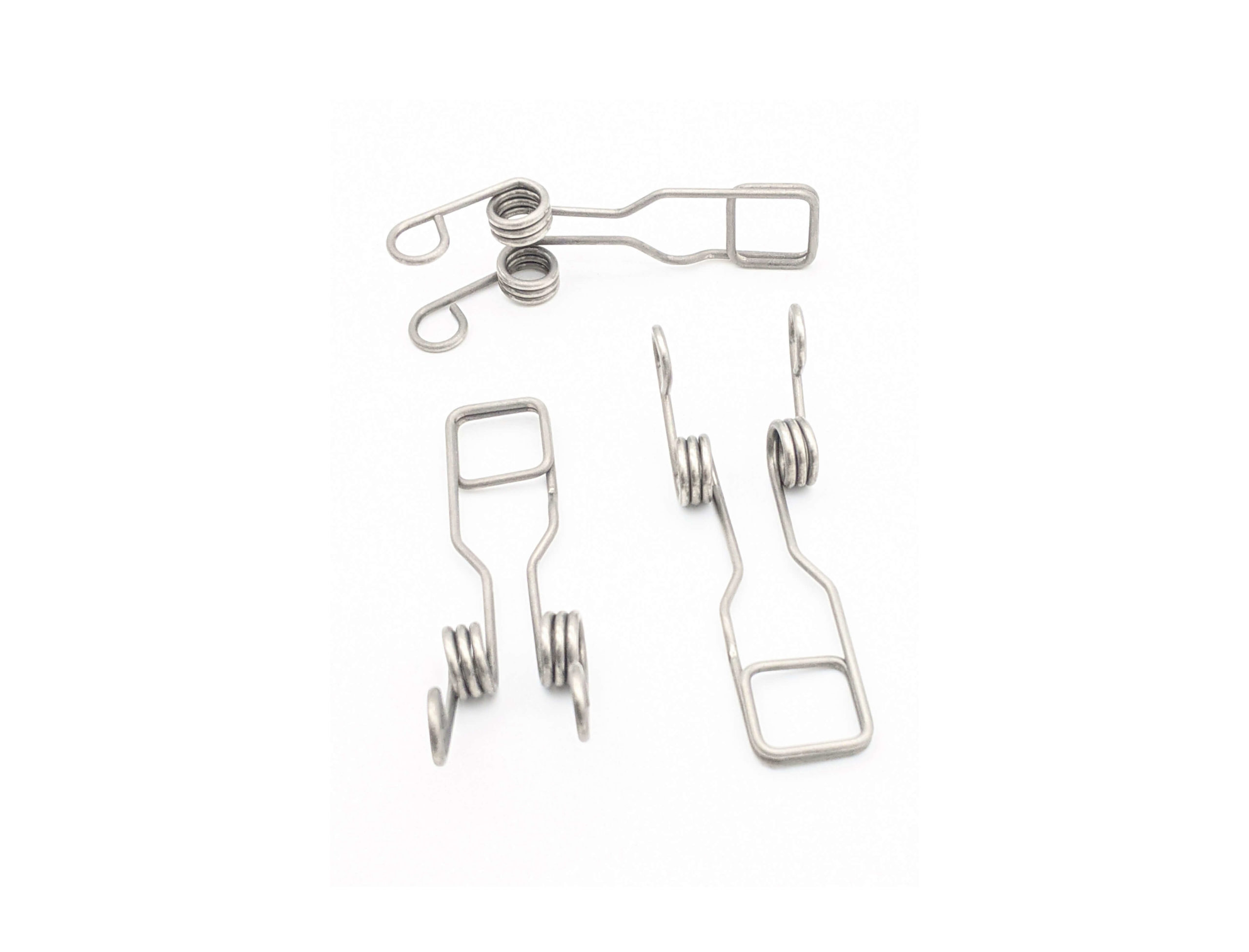

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Working on your car's suspension can be a daunting task, especially when it comes to dealing with those tightly wound coil springs. But fear not! A coil spring compressor tool

Coil springs are the unsung heroes of your car's suspension system, responsible for providing a smooth ride by absorbing bumps and dips in the road. However, these powerful components store a tremendous amount of potential energy, making them incredibly dangerous to handle without the proper tools. That's where a coil spring compressor tool comes in. This ingenious device allows you to safely compress the spring, reducing its stored energy and enabling you to remove or install it without risking serious injury.

Just like the cars they service, coil spring compressors come in various shapes and sizes, each designed for specific applications and levels of expertise. Let's take a look at the most common types:

1. Wall-Mounted Compressor: This heavy-duty option is often found in professional garages and workshops. It offers unparalleled stability and compression power, making it ideal for handling large and stubborn springs. However, its size and price tag might not be suitable for the average DIY enthusiast.

2. Strut Compressor: Specifically designed for MacPherson strut suspensions, this type of compressor is more compact and easier to maneuver. It's perfect for tackling smaller springs found in many modern vehicles.

3. External Compressor: As the name suggests, this type clamps onto the outside of the coil spring, allowing you to compress it without removing the strut assembly. While convenient for some applications, its gripping power might be limited compared to internal compressors.

4. Internal Compressor: This type works from within the spring itself, providing a more secure and controlled compression. It's generally considered the safest option for DIYers as it minimizes the risk of the spring slipping out during the process.

Remember, compressed coil springs are like ticking time bombs. Always prioritize safety when using a compressor tool. Here are some crucial precautions to keep in mind:

1. Wear Safety Glasses: Protect your eyes from potential flying debris or spring fragments.

2. Use Heavy-Duty Gloves: Shield your hands from sharp edges and pinch points.

3. Double-Check the Setup: Ensure the compressor is securely attached to the spring before applying any pressure.

4. Compress Slowly and Evenly: Avoid sudden movements or excessive force, as this can cause the spring to buckle or slip.

5. Never Work Under a Compressed Spring: Always release the tension before making any adjustments or inspections.

Selecting the right coil spring compressor tool can be overwhelming, especially with so many options available. Consider these factors to make an informed decision:

1. Vehicle Type: Different vehicles have different suspension systems, so choose a compressor compatible with your car's specific setup.

2. Spring Size and Strength: Ensure the compressor can handle the size and weight of your coil springs.

3. Frequency of Use: If you're a frequent DIYer, invest in a durable and reliable tool. For occasional use, a more affordable option might suffice.

4. Budget: Coil spring compressors range in price, so set a budget beforehand and explore options within your price range.

Once you've chosen your tool, follow these expert tips to ensure a smooth and successful operation:

1. Lubricate the Threads: Applying lubricant to the compressor's threaded components ensures smooth operation and reduces wear and tear.

2. Use a Ratchet or Breaker Bar: Achieve better leverage and control over the compression process by using a ratchet or breaker bar instead of relying solely on hand strength.

3. Work in a Well-Lit Area: Ensure proper visibility to avoid mistakes and enhance safety.

4. Inspect the Spring After Compression: Before removing the spring, carefully inspect it for any signs of damage or deformation.

A coil spring compressor tool is an indispensable asset for any DIY enthusiast or professional mechanic tackling suspension work. By understanding the different types, prioritizing safety precautions, and following expert tips, you can confidently and effectively compress coil springs, making your suspension projects a breeze! Remember, knowledge is power, and when it comes to working with powerful components like coil springs, a little knowledge can go a long way in ensuring your safety and success.

With the right coil spring compressor tool and a healthy dose of caution, you can confidently conquer any suspension project that comes your way. Always remember to prioritize safety and never underestimate the potential energy stored within those tightly wound coils. Happy wrenching!Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.