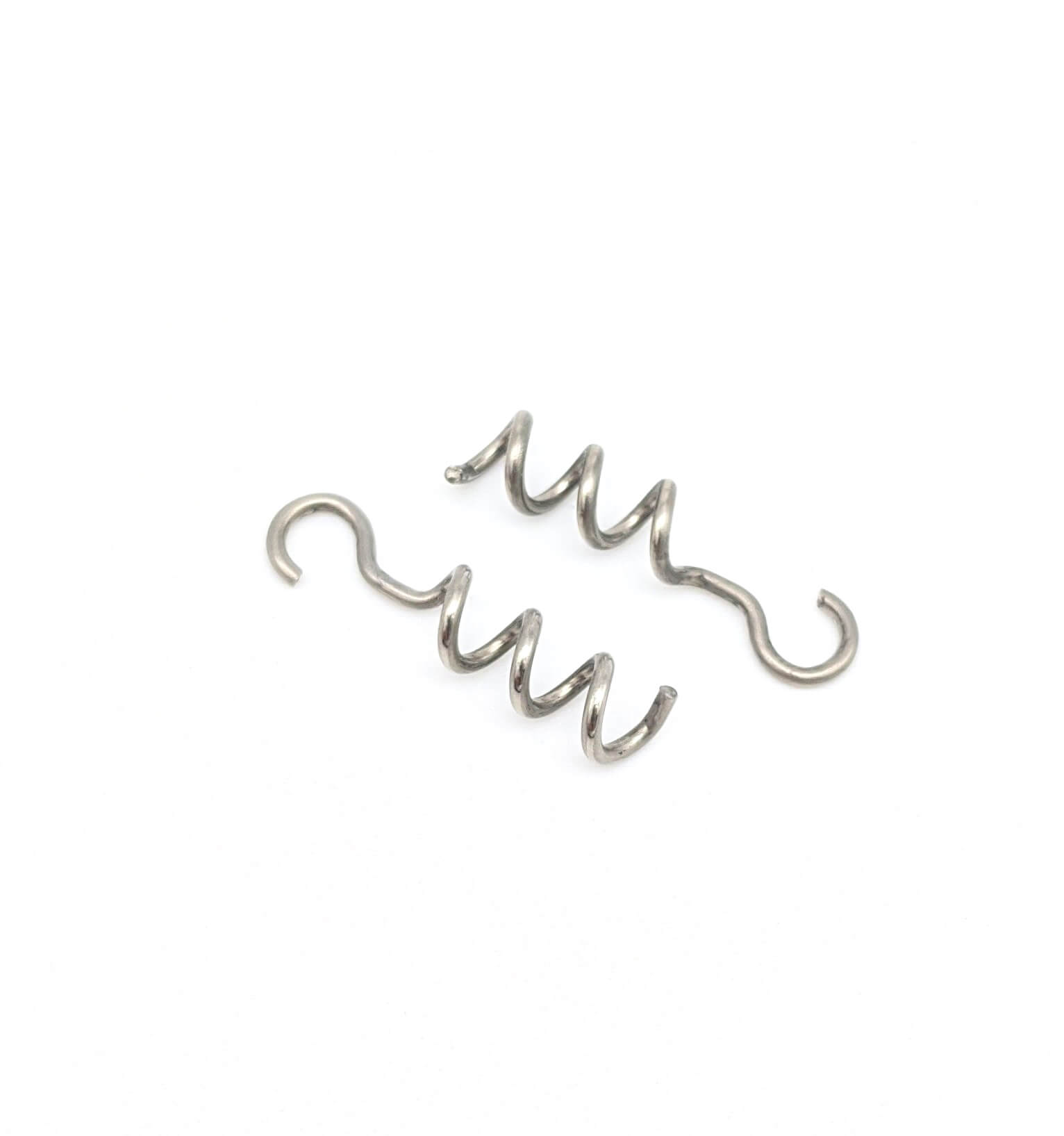

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Coil springs, ubiquitous in countless applications, are marvels of engineering that store and release mechanical energy. Their ability to compress under load, returning to their original shape with a restoring

Coil springs, ubiquitous in countless applications, are marvels of engineering that store and release mechanical energy. Their ability to compress under load, returning to their original shape with a restoring force, makes them essential components in various mechanical systems. In this article, we delve into the fascinating world of coil spring compression, exploring the underlying physics, factors influencing compression, and its diverse applications in everyday life.

Coil spring compression is the process of applying an axial force to a coil spring, causing it to shorten in length. This compression is accompanied by the storage of potential energy within the spring, which is subsequently released upon removal of the load, restoring the spring to its original length. The amount of compression a coil spring undergoes depends on several factors, including:

The relationship between force and compression is typically described by Hooke's Law, which states that the force exerted by a spring is directly proportional to its displacement from its equilibrium position. This relationship holds true for most springs within their elastic limit. Beyond this limit, the spring may permanently deform or fail.

Coil spring compression is employed in a wide array of applications, impacting our daily lives in countless ways. Here are some notable examples:

When selecting coil springs for a particular application, several factors should be considered:

Coil spring compression is a fundamental principle in mechanics, underpinning countless innovations and advancements across diverse fields. Understanding the factors influencing compression, its diverse applications, and the considerations for selecting appropriate springs is essential for engineers, designers, and anyone involved in developing mechanical systems. As technology continues to evolve, the role of coil springs is likely to expand further, contributing to the development of innovative and efficient solutions for future challenges.

From suspension systems to everyday objects, coil springs are indispensable components that make our lives easier and more efficient. By understanding the mechanisms of coil spring compression, we gain insights into the fundamental principles that drive countless technologies around us. As we continue to explore the potential of these remarkable devices, we can expect to witness even more ingenious applications of coil spring compression in the years to come.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.