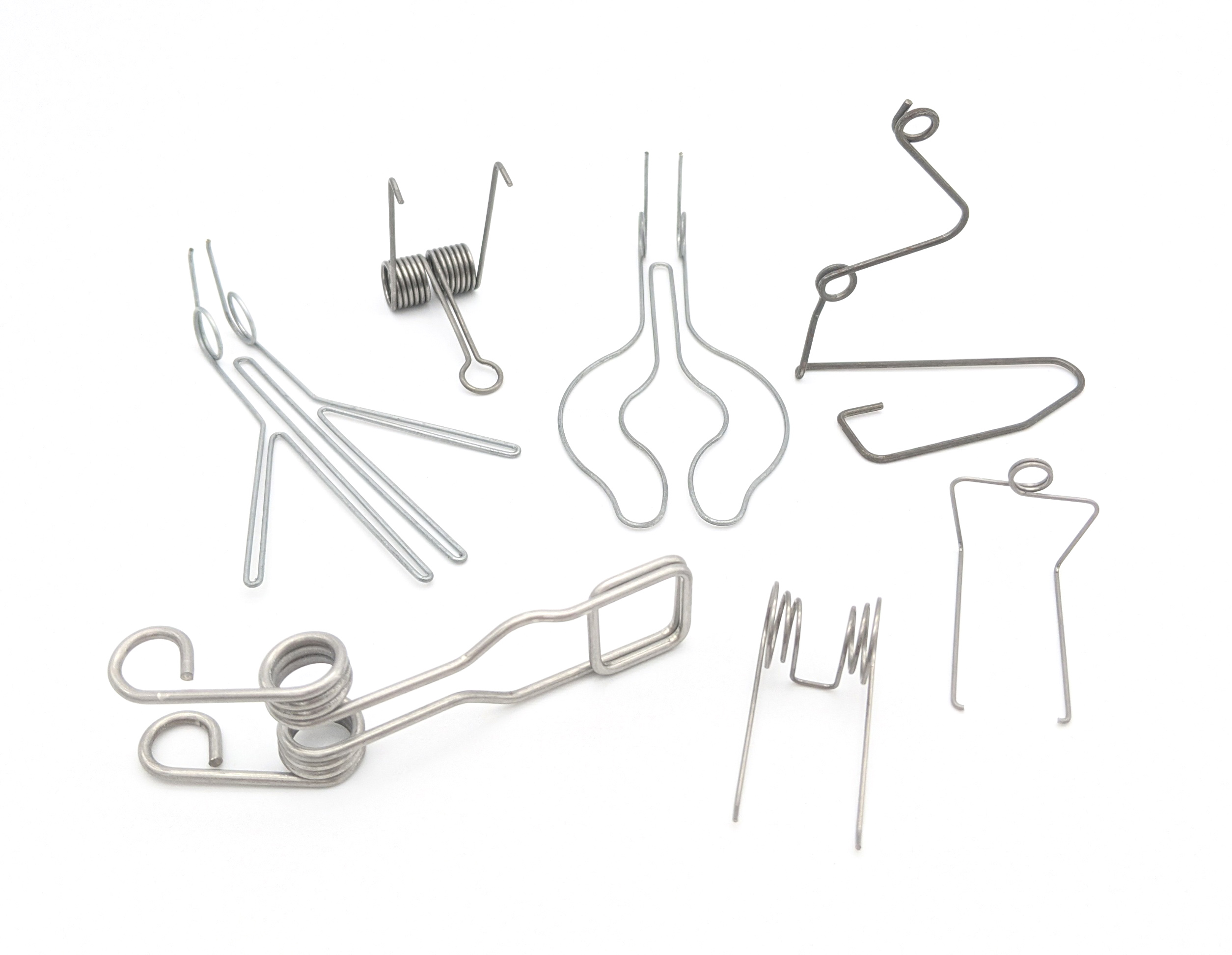

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Coil springs are ubiquitous in mechanical systems, playing a critical role in absorbing shock, storing energy, and providing a restoring force. Understanding the principles of coil spring compression is crucial

Coil springs are ubiquitous in mechanical systems, playing a critical role in absorbing shock, storing energy, and providing a restoring force. Understanding the principles of coil spring compression is crucial for engineers and designers who work with these essential components. This article delves into the mechanics of coil spring compression, exploring its key factors, applications, and practical considerations. We'll examine the relationship between force, deflection, and spring rate, as well as the influence of factors like spring material, geometry, and end conditions.

A coil spring, when subjected to an axial force, experiences compression. This compression is characterized by the shortening of the spring's length, a phenomenon that arises from the elastic properties of the spring material. The force required to compress a coil spring is directly proportional to the amount of compression, a relationship governed by Hooke's Law.

Hooke's Law, a cornerstone of spring mechanics, states that the force (F) required to compress or extend a spring is directly proportional to the displacement (x) from its equilibrium position. Mathematically, this relationship is expressed as:

F = kx

where 'k' represents the spring constant, a measure of the spring's stiffness. A higher spring constant signifies a stiffer spring, requiring greater force to achieve a given compression.

The spring constant is a crucial parameter in designing and selecting springs for various applications. It's determined by several factors, including the spring material, wire diameter, coil diameter, number of coils, and end conditions. For example, a spring made from a stronger material will have a higher spring constant, while a spring with a larger coil diameter will have a lower spring constant.

Coil springs find diverse applications across various industries, exploiting their ability to store and release energy, absorb shocks, and provide a restoring force.

Here's a glimpse into some key areas where coil spring compression plays a vital role:

The compression behavior of a coil spring is influenced by several factors, each contributing to its overall performance.

Spring Material: The choice of material is paramount in determining a spring's strength, stiffness, and fatigue resistance. Steel, stainless steel, and other metal alloys are commonly used for their high strength-to-weight ratio and resilience. The material's elastic modulus, a measure of its stiffness, plays a significant role in the spring's compression characteristics.

Spring Geometry: The geometry of the coil spring significantly affects its compression behavior. The wire diameter, coil diameter, and number of coils are key parameters influencing the spring constant. A thicker wire diameter leads to a higher spring constant, while a larger coil diameter results in a lower spring constant.

End Conditions: The way a coil spring is attached to the system affects its behavior. Common end conditions include plain ends, ground ends, and closed ends, each affecting the effective length of the spring and the overall spring constant.

Temperature: Temperature fluctuations can impact the material properties of the spring, leading to changes in stiffness and compression behavior. This effect is particularly relevant in applications where the spring operates in extreme temperatures.

When working with coil spring compression, several practical considerations ensure proper design and operation:

Coil spring compression is a fundamental concept in mechanical engineering, with wide-ranging applications across various industries. Understanding the mechanics of coil spring compression, including the factors influencing its behavior, is crucial for designing and selecting these essential components. By carefully considering the spring material, geometry, end conditions, and other relevant factors, engineers can ensure the efficient and reliable operation of coil springs in their respective applications.

From automotive suspensions to medical devices, coil springs play a vital role in numerous applications, showcasing the power and versatility of this fundamental mechanical element. By mastering the principles of coil spring compression, we can unlock the full potential of these essential components, ensuring efficient and reliable performance in diverse mechanical systems.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.