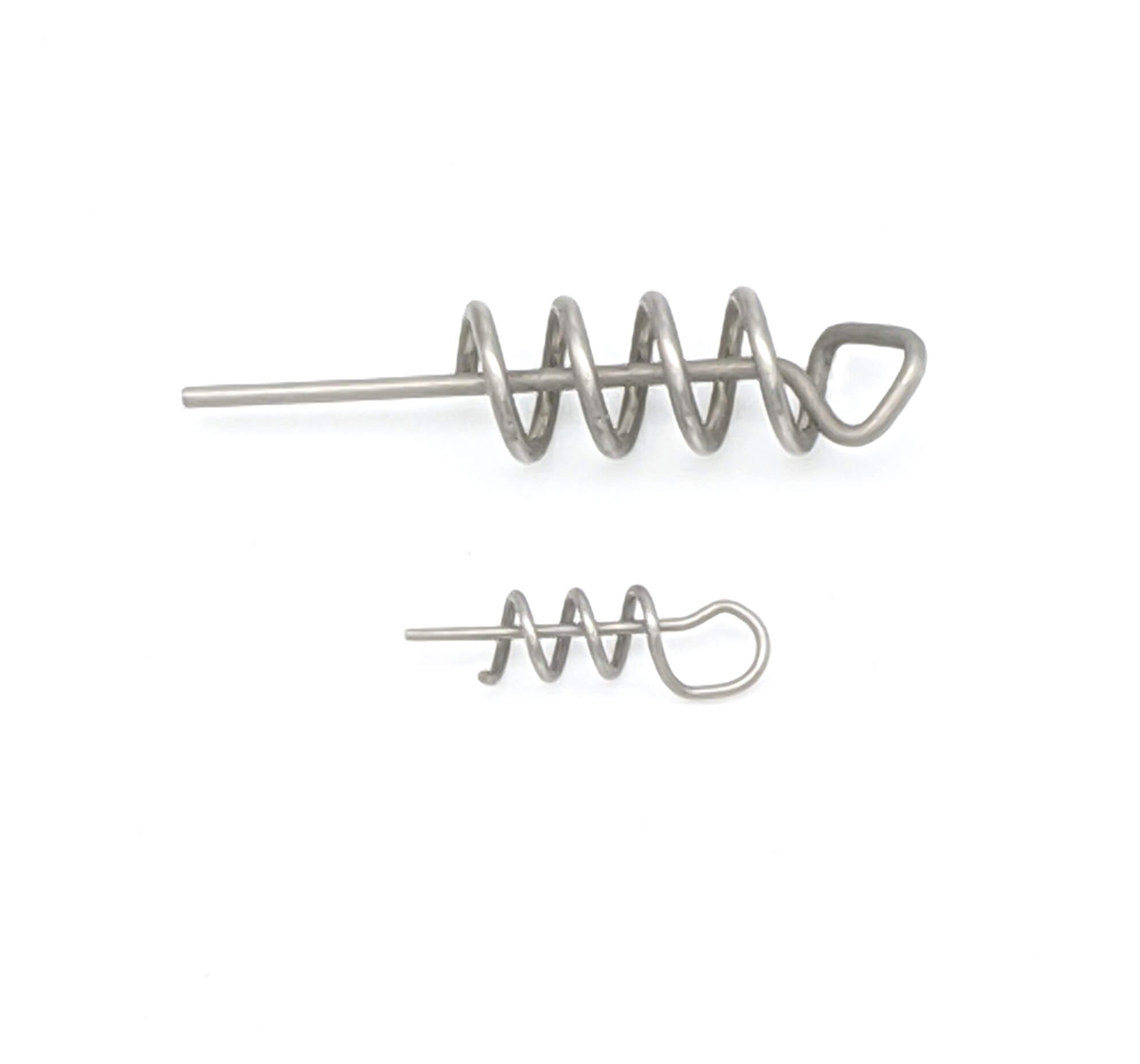

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Coil spring compression is a fundamental concept in mechanical engineering, playing a crucial role in countless applications. It involves applying force to a coil spring, causing it to shorten. Understanding

Coil spring compression is a fundamental concept in mechanical engineering, playing a crucial role in countless applications. It involves applying force to a coil spring, causing it to shorten. Understanding the mechanics of coil spring compression is vital for engineers and designers, as it allows them to optimize the performance of various systems. This article dives deep into the intricacies of coil spring compression, exploring its underlying principles, practical applications, and the factors that govern its behavior.

At its core, coil spring compression involves applying an external force to a coil spring, resulting in a decrease in its length. This force, known as the compression force, acts along the axis of the spring. As the force is applied, the spring coils become closer together, storing energy within its elastic structure. The amount of compression, or the change in length, is directly proportional to the applied force, a principle known as Hooke's Law.

Imagine a simple scenario – a weight resting on a spring. The weight exerts a downward force on the spring, causing it to compress. The spring, in turn, pushes back with an equal and opposite force, resisting the compression. This back-and-forth action creates a balanced system, where the spring's compression is determined by the weight's force.

To delve deeper into coil spring compression, understanding some essential concepts is crucial:

Spring Rate: This refers to the stiffness of the spring, indicating how much force is required to compress it a certain distance. Higher spring rates correspond to stiffer springs, requiring more force for compression. Spring rate is measured in units of force per distance, like N/mm or lbf/in.

Solid Height: This is the minimum length the spring can reach when fully compressed. It's important to consider the solid height to prevent the spring from being overcompressed, which can lead to damage.

Free Length: This refers to the spring's length when it is uncompressed and relaxed.

Deflection: The amount of compression a spring undergoes, measured as the difference between the free length and the compressed length.

Several factors influence the compression behavior of a coil spring, making it crucial to consider them during design and selection:

Spring Material: The material used for the coil spring significantly affects its compression characteristics. Spring steel, due to its high elastic modulus, is commonly used, but other materials like bronze or titanium may be employed for specific applications.

Coil Diameter: The diameter of the coil directly impacts the spring's stiffness. Larger coil diameters generally result in lower spring rates, meaning less force is needed for compression.

Wire Diameter: The diameter of the wire used to form the coil also affects stiffness. Thicker wires result in stiffer springs.

Number of Coils: The number of active coils in the spring plays a crucial role. More coils generally lead to lower spring rates, as the energy is distributed across more coils.

End Type: The design of the spring's ends can influence its compression behavior, particularly how the spring engages with the applied load.

Coil spring compression finds a wide range of applications in various industries, encompassing:

Automotive Industry: Suspension systems in vehicles rely heavily on coil springs. Their compression and rebound characteristics provide a smooth ride, absorbing shocks and vibrations from the road.

Industrial Machinery: Coil springs are used in numerous industrial applications, such as in presses, lifting devices, and clamping mechanisms. Their ability to store and release energy makes them ideal for these tasks.

Consumer Products: You'll find coil springs in everyday items like pens, toys, and door closers. Their versatility makes them an integral component in many products.

Aerospace: Even in space, coil springs find applications. They are used in actuators, landing gear, and other systems where controlled compression is required.

While coil springs offer numerous benefits, it's important to consider certain factors before implementing them in a design:

Fatigue: Repeated compression and decompression can lead to fatigue in the spring material, eventually causing failure. Understanding the spring's fatigue life is vital for long-term reliability.

Environment: The operating environment can affect spring performance. Factors like temperature, humidity, and corrosive agents need to be considered to ensure the spring's integrity.

Damping: In some applications, damping is desired to reduce oscillations or vibrations. This can be achieved using various methods like adding dampeners or selecting materials with inherent damping properties.

The world of coil spring compression extends beyond the fundamentals discussed here. There are advanced topics and specialized types of springs worth exploring, such as:

Variable Rate Springs: These springs exhibit a changing spring rate during compression, allowing for tailored force-displacement characteristics.

Torsion Springs: Unlike compression springs, torsion springs are designed to resist twisting forces. They find applications in clutches, brakes, and other rotating mechanisms.

Belleville Washers: These disc-shaped springs offer high compression forces in a small package. They are commonly used in clamping applications.

Coil spring compression is a fundamental concept with far-reaching implications. Understanding its principles, considering relevant factors, and selecting appropriate spring types are essential for engineers and designers looking to harness the power of these versatile components. Whether in automotive systems, industrial machinery, or everyday products, coil springs continue to play a critical role in modern engineering, enabling precise control and efficient energy storage.

The versatility and reliability of coil springs make them an indispensable component in various industries. By understanding the principles of coil spring compression, engineers can optimize their designs, ensuring efficient performance and long-term durability. From the simplest of applications to the most complex engineering feats, coil springs stand as a testament to the ingenuity and practicality of mechanical design.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.