Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Coil spring clamps, often referred to as spring clamps, are indispensable tools in a wide array of applications. They provide a secure and reliable way to hold objects together, whether

Coil spring clamps, often referred to as spring clamps, are indispensable tools in a wide array of applications. They provide a secure and reliable way to hold objects together, whether it's during assembly, repair, or simply for temporary clamping. These versatile clamps are known for their simplicity, ease of use, and robust design. In this article, we'll delve into the world of coil spring clamps, exploring their construction, working principle, types, applications, and factors to consider when choosing the right clamp for your specific needs.

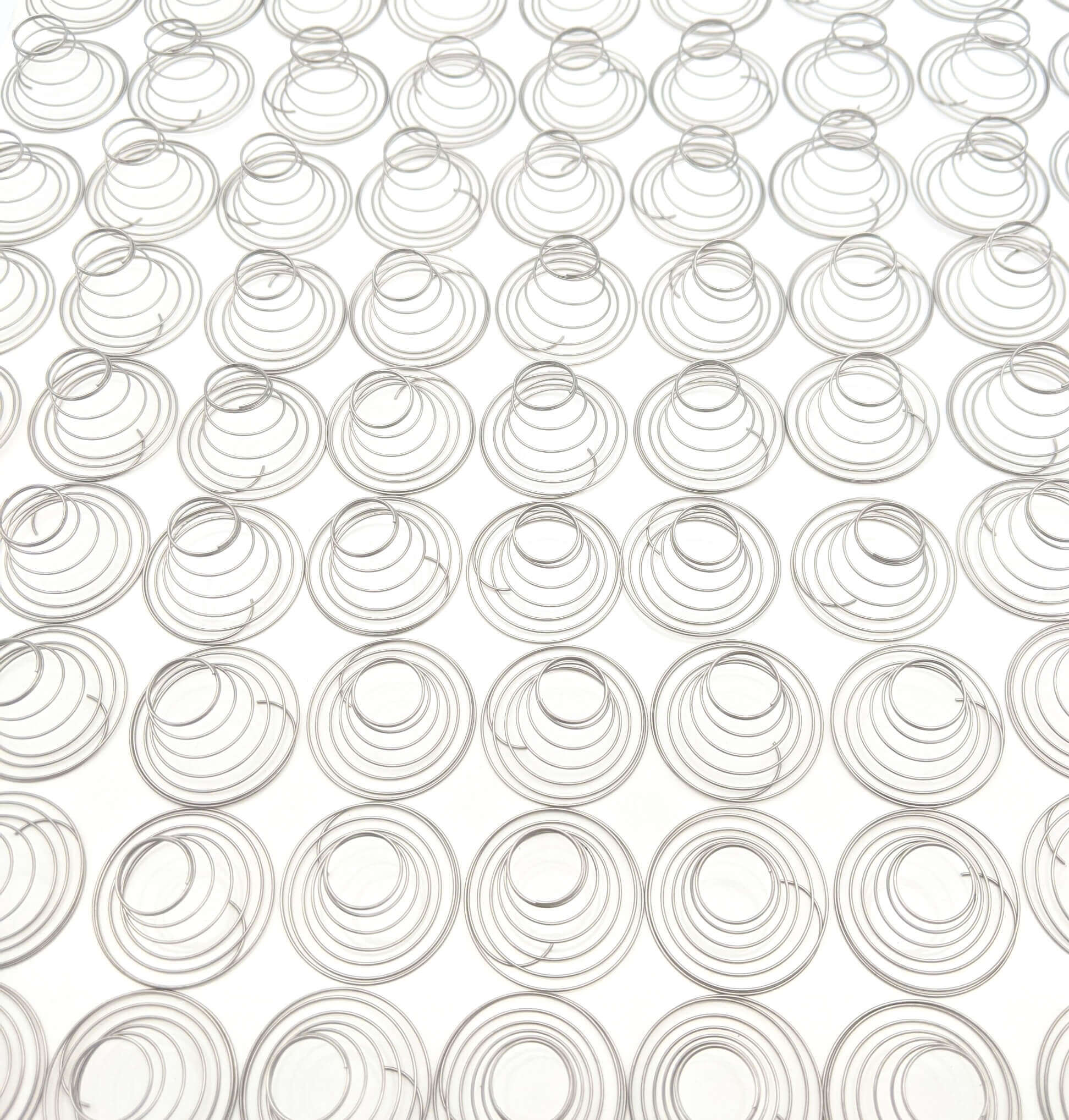

Coil spring clamps, also known as spring clamps, are mechanical fasteners that utilize the force of a spring to apply clamping pressure. Their design is relatively straightforward, typically consisting of a handle, a spring mechanism, and jaws that grip the workpiece. The handle controls the spring tension, allowing you to adjust the clamping force as needed. The jaws are typically made of durable materials like steel or aluminum, providing a secure grip on a variety of materials.

The beauty of coil spring clamps lies in their simplicity and effectiveness. Unlike more complex clamps that may require intricate mechanisms, these clamps offer a quick and easy way to secure objects. Simply squeeze the handle to compress the spring, open the jaws, place the workpiece in position, and release the handle to apply clamping force. The spring then holds the workpiece securely in place until you're ready to release it.

Coil spring clamps come in a multitude of sizes and configurations, each designed to address specific applications. Let's explore some of the most common types:

Heavy-duty clamps are built to withstand significant clamping forces. They often feature a robust construction, larger jaws, and a more powerful spring mechanism. These clamps are ideal for securing large and heavy objects or materials that require a strong grip.

Light-duty clamps are designed for smaller, lighter applications. They typically have smaller jaws and a weaker spring mechanism. These clamps are perfect for holding delicate materials or objects that require a gentle touch.

Right-angle clamps offer a unique design with jaws that are positioned perpendicular to the handle. This configuration is ideal for clamping objects in tight spaces or at awkward angles, making them particularly useful in woodworking and construction projects.

Adjustable clamps allow you to fine-tune the clamping force by adjusting the position of the spring mechanism. This versatility is essential for applications where precise clamping pressure is critical.

Coil spring clamps are ubiquitous in various industries and applications, thanks to their versatility, ease of use, and affordability. Here are some key areas where these clamps shine:

In manufacturing environments, coil spring clamps are essential for holding components securely during assembly processes. They ensure parts remain in place while being joined together, minimizing misalignment and ensuring a quality finished product.

Woodworkers rely heavily on coil spring clamps for holding pieces of wood together during gluing, clamping boards for cutting or shaping, and securing workpieces for finishing operations.

In the automotive world, coil spring clamps are used for a wide range of tasks. They help secure hoses, wires, and other components during repairs, preventing damage and ensuring a safe and efficient process.

From simple crafts to more ambitious home improvement projects, coil spring clamps prove invaluable for holding objects in place, ensuring stability and preventing unwanted movement. They are particularly useful for DIY enthusiasts who want to tackle projects around the house without investing in a large toolkit.

Choosing the right coil spring clamp for your specific application can make all the difference. Here are some essential factors to consider:

The clamping force required will depend on the weight and size of the workpiece. For heavy objects, you'll need a clamp with a strong spring mechanism, while for lighter materials, a light-duty clamp will suffice.

The size and shape of the jaws should be appropriate for the workpiece. Ensure the jaws can grip the object securely without slipping or marring the surface.

The handle should be comfortable to grip and operate, especially if you're working on a project for extended periods. Consider ergonomic handles for increased comfort.

The jaws and spring mechanism should be made from durable materials capable of withstanding the intended clamping force and repeated use.

Coil spring clamps come in a wide range of prices depending on their features and quality. Choose a clamp that balances your budget with your project's needs.

Coil spring clamps are a simple yet powerful tool that plays a vital role in countless applications. Their versatility, ease of use, and affordability make them a staple in workshops, garages, and homes alike. By understanding the different types, applications, and factors to consider when choosing a clamp, you can ensure you select the perfect clamp for your specific needs, making your projects safer, more efficient, and ultimately more successful.

In conclusion, coil spring clamps are a valuable tool for securing objects, making them essential in various settings. Their simple design, robust construction, and diverse types make them ideal for everything from manufacturing and woodworking to automotive repair and home DIY projects. By considering factors like clamping force, jaw size, handle design, and durability, you can choose the right coil spring clamp for your specific needs, ensuring secure and reliable fastening for any project.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.