Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

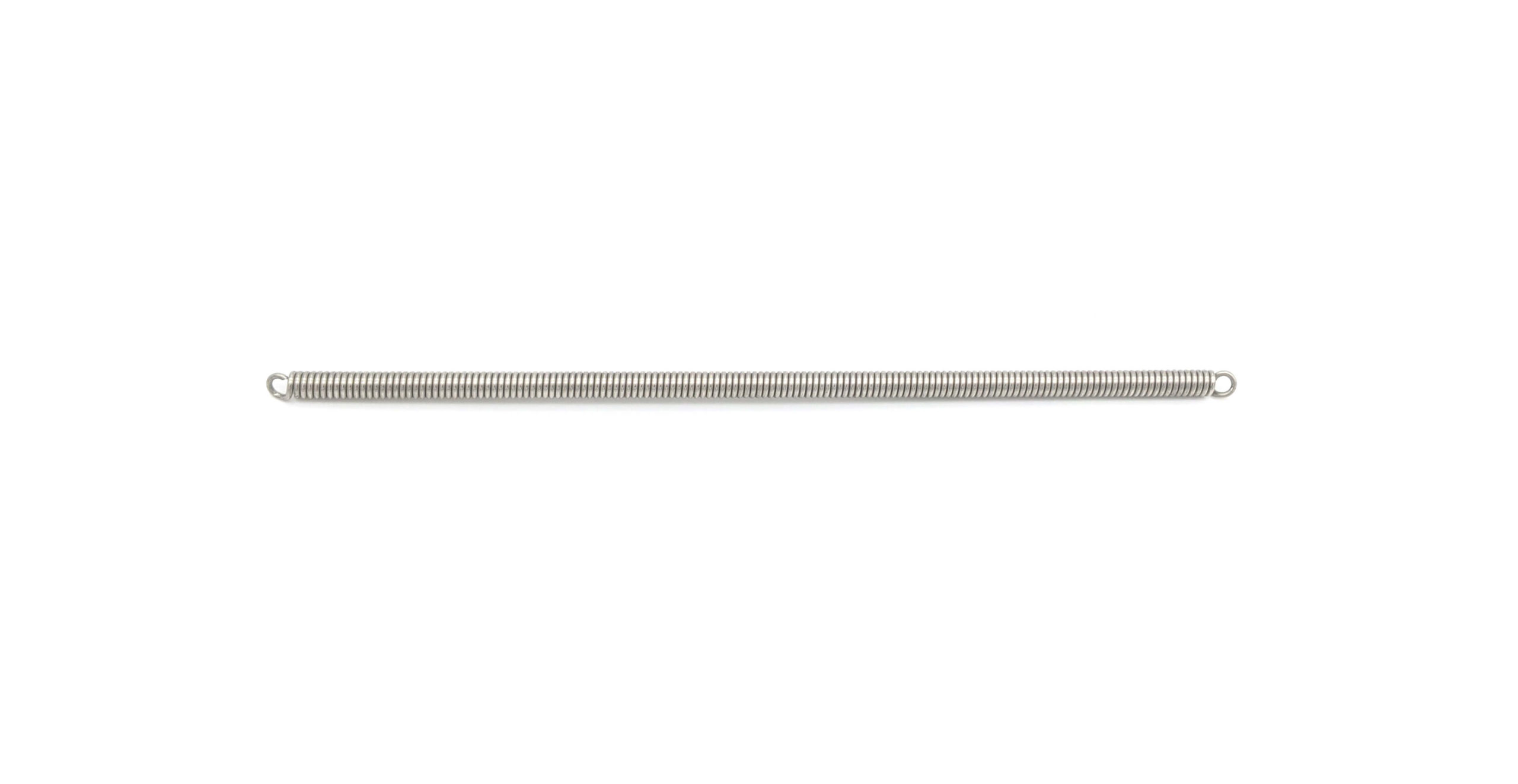

Cantilever springs, also known as single-ended springs, are ubiquitous in mechanical systems. They are essentially helical springs that are fixed at one end and free at the other, offering a

Cantilever springs, also known as single-ended springs, are ubiquitous in mechanical systems. They are essentially helical springs that are fixed at one end and free at the other, offering a unique set of characteristics that make them perfect for various applications. These springs are known for their robustness, high load-carrying capacity, and versatility, making them a preferred choice in various industries. This article delves into the fascinating world of cantilever springs, exploring their design, applications, and the advantages that make them so valuable.

Cantilever springs are distinguished by their distinctive design, which incorporates a helical coil fixed at one end and free at the other. This fixed end, often referred to as the anchor point, acts as the pivot point for spring deflection. The free end, on the other hand, is where the load is applied. As the force is applied, the spring bends or deflects, storing potential energy. The spring's deflection is proportional to the applied force, and this relationship is determined by the spring's stiffness, which is a measure of how resistant it is to deformation.

The design of a cantilever spring involves careful consideration of factors like the material, coil diameter, wire diameter, number of coils, and free length. The material choice is crucial and often depends on the application's specific requirements. High-strength steel alloys are commonly used due to their excellent resilience and durability. The wire diameter determines the spring's stiffness, with thicker wires resulting in higher stiffness. The number of coils and free length are also critical factors in determining the spring's deflection characteristics.

Cantilever springs find diverse applications across a wide range of industries, proving their versatility and practicality. Some of the most common applications include:

1. Automotive Industry: Cantilever springs play a crucial role in vehicle suspension systems, ensuring a comfortable ride and proper handling. They are used in leaf springs, coil springs, and torsion bars, providing the necessary support and resilience for the vehicle's weight and road conditions.

2. Aerospace Industry: In the aerospace sector, cantilever springs are integral to aircraft landing gear and flap systems. They provide shock absorption during landings and control the movement of flaps, ensuring safe and efficient operation.

3. Industrial Machinery: Cantilever springs are widely used in industrial machinery to provide tension, support, and load-bearing capabilities. They are often found in clutches, brakes, and other mechanical systems requiring controlled movement and resilience.

4. Medical Devices: In medical equipment, cantilever springs are vital for precise movements and load-bearing applications. They are incorporated into devices like surgical instruments, prosthetics, and diagnostic equipment, ensuring reliability and performance.

5. Consumer Products: From door hinges to spring-loaded mechanisms in appliances, cantilever springs are present in various consumer products. Their ability to provide controlled movement, support, and resilience makes them essential components in everyday items.

The popularity of cantilever springs can be attributed to their numerous advantages, which make them a preferred choice in various engineering applications. Some of the key benefits include:

1. High Load-Carrying Capacity: Cantilever springs are designed to withstand significant loads, making them suitable for demanding applications. This high load-carrying capacity is attributed to their robust construction and efficient load distribution.

2. Flexibility and Versatility: The design flexibility of cantilever springs allows for customization to suit specific requirements. They can be designed with varying stiffness, lengths, and configurations to accommodate diverse applications.

3. Compact Design: Compared to other spring types, cantilever springs often offer a more compact design, which is particularly beneficial in applications where space is limited.

4. Resistance to Fatigue: Cantilever springs exhibit excellent fatigue resistance, ensuring their reliability and longevity under repeated loading cycles.

5. Cost-Effectiveness: Cantilever springs are typically cost-effective solutions, especially when compared to more complex spring types. This affordability makes them suitable for a wide range of applications.

While cantilever springs offer numerous benefits, it is crucial to consider some challenges and design considerations to ensure optimal performance and longevity.

1. Stress Concentration: The fixed end of a cantilever spring experiences a high concentration of stress, which can potentially lead to failure if not properly addressed. Careful material selection and design optimization are crucial to minimize stress concentrations.

2. Fatigue: Although cantilever springs exhibit excellent fatigue resistance, prolonged exposure to cyclic loading can still lead to fatigue failure. Understanding the fatigue limit of the material and implementing appropriate design measures are essential for preventing premature failure.

3. Instability: Cantilever springs can exhibit instability under certain loading conditions, leading to buckling or collapse. Careful design considerations, including appropriate support structures, are necessary to prevent instability.

Cantilever springs continue to play a vital role in modern engineering, with ongoing innovations and advancements in design and materials. The use of advanced materials like composites and alloys is increasing the load-carrying capacity, fatigue resistance, and corrosion resistance of cantilever springs, opening new possibilities for their applications. Furthermore, the integration of computer-aided design and analysis tools is enabling engineers to optimize spring designs for improved performance and efficiency. The future of cantilever springs looks bright, with ongoing research and development promising further advancements in their capabilities and applications.

Cantilever springs are fundamental components in countless mechanical systems, offering a unique combination of strength, versatility, and cost-effectiveness. From automotive suspension systems to medical devices, their presence is felt across diverse industries. As engineering continues to evolve, cantilever springs are poised to play an even greater role in shaping the future of technology. Their adaptability and proven reliability make them indispensable for various applications, ensuring continued innovation and advancements in mechanical engineering.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.