Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Compression springs are essential components in a wide range of applications, from simple door hinges to complex machinery. Whether you're an engineer designing a new product or a DIY enthusiast

Compression springs are essential components in a wide range of applications, from simple door hinges to complex machinery. Whether you're an engineer designing a new product or a DIY enthusiast tackling a home project, understanding how to buy compression springs is crucial. This comprehensive guide will walk you through the key factors to consider when selecting the right spring, helping you make an informed decision that meets your specific requirements.

Compression springs are designed to absorb and store energy when compressed. They work by resisting a force that pushes them together, storing potential energy that is released as the spring expands back to its original length. This fundamental principle makes them ideal for a variety of applications where controlled movement, shock absorption, or energy storage is required.

The choice of compression spring depends on several factors, including the application, the load it needs to handle, the space available, and the desired spring rate.

Before you start shopping for compression springs, it's important to understand the key factors that will influence your selection. Here's a breakdown of the most crucial elements:

The spring rate is a measure of how much force is required to compress the spring by a specific distance. It's typically expressed in pounds per inch (lbs/in) or newtons per millimeter (N/mm). A higher spring rate indicates a stiffer spring that requires more force to compress.

The spring rate is a critical factor in determining how a spring will behave in your application. If you need a spring to provide strong resistance to compression, you'll need a higher spring rate. Conversely, if you require a spring that compresses easily, you'll need a lower spring rate.

Compression springs are typically made from various metals, each possessing unique properties that influence their performance. Here are some common spring materials and their characteristics:

Choosing the right material depends on the specific requirements of your application. Consider factors such as the environment, the load to be handled, and the desired durability.

The spring diameter refers to the diameter of the coil of the spring, while the wire diameter is the thickness of the wire used to make the spring. These two dimensions play a critical role in determining the spring's capacity, stiffness, and overall size.

A larger spring diameter generally translates to a larger spring with a higher capacity. A thicker wire diameter results in a stiffer spring that can handle heavier loads.

The free length of a compression spring is its overall length when it's not under any load. Compression travel is the distance the spring can be compressed before it reaches its solid height, the point where the coils touch each other.

Determining the appropriate free length and compression travel is essential for ensuring that the spring fits within your application's constraints and can compress to the desired extent without bottoming out.

Compression springs can have various end configurations, each designed for specific applications. Here are some common end types:

Select the end configuration that best suits your application's requirements. For instance, if you need a spring that fits tightly within a specific space, a ground end configuration might be necessary.

Compression springs are readily available from a variety of suppliers, both online and offline. Here are some resources you can explore:

When choosing a supplier, consider factors such as price, availability, shipping costs, and customer service. You may also want to check customer reviews to get an idea of the supplier's reputation and reliability.

Here are some practical tips to help you make the most of your compression spring purchase:

Buying compression springs may seem straightforward, but understanding the key factors involved can help you make a more informed decision. By considering spring rate, material, diameter, length, end types, and the overall application, you can ensure that you select the right spring for your needs. Whether you're an engineer, a hobbyist, or a business owner, this guide provides valuable insights into the world of compression springs, helping you find the perfect spring for your next project.

Remember, when in doubt, consult with a professional or a knowledgeable supplier. They can provide valuable guidance and ensure that you select the right compression spring for your specific application, ultimately leading to successful and reliable results.

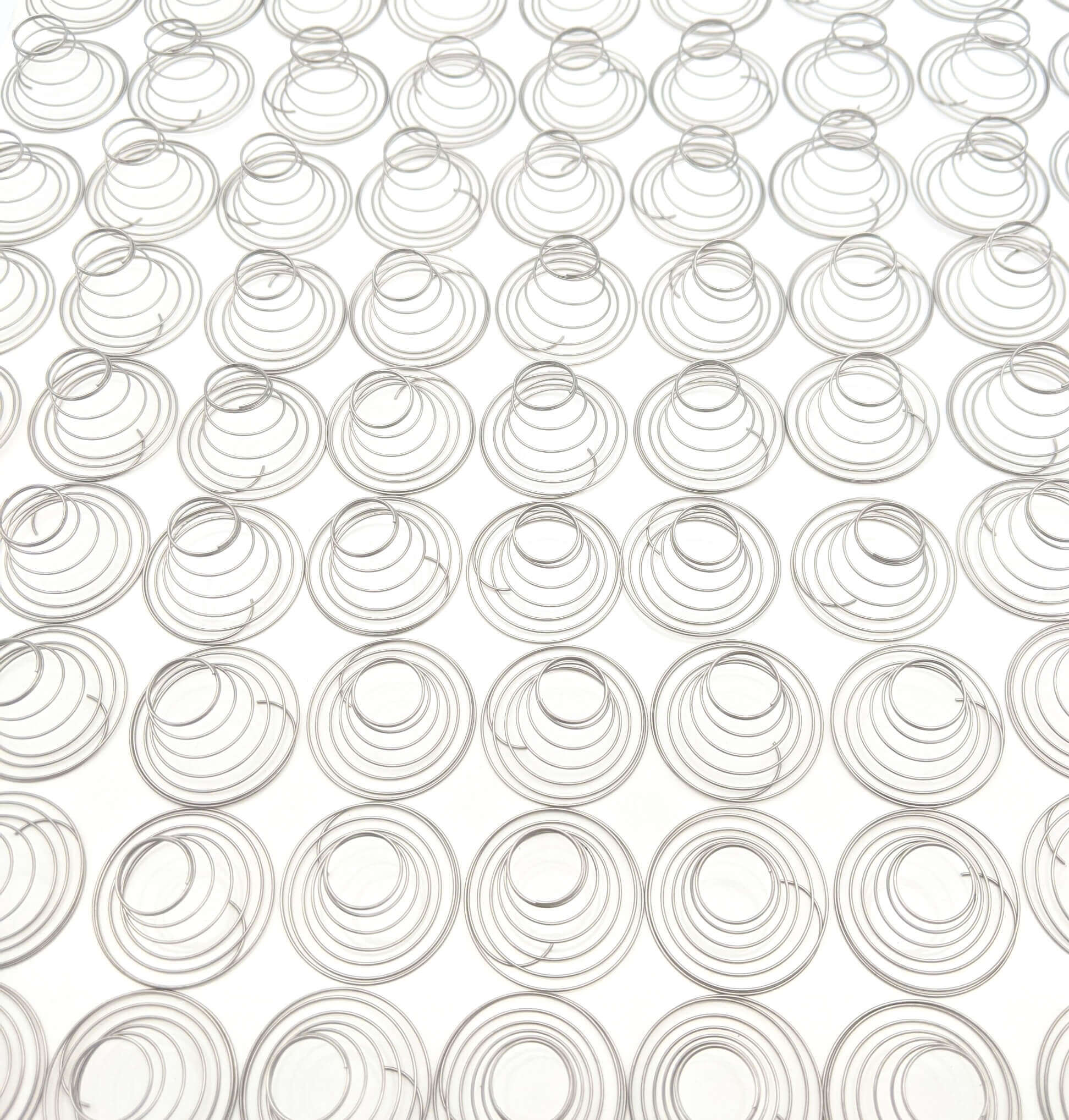

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.