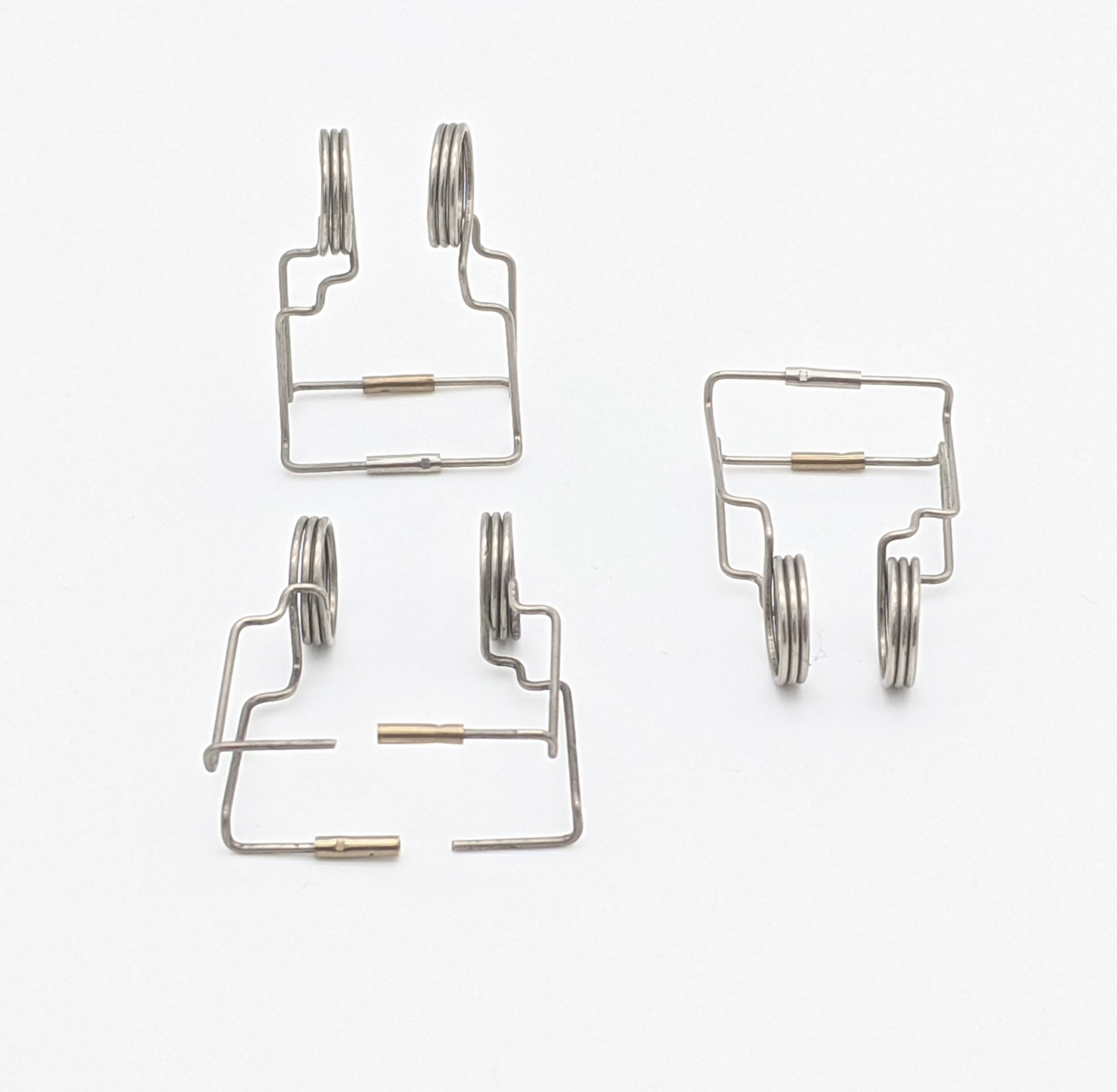

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the vast world of mechanical components, there exists a humble yet crucial element that often goes unnoticed: the Belleville washer. This seemingly simple, conical disc-shaped spring packs an impressive

In the vast world of mechanical components, there exists a humble yet crucial element that often goes unnoticed: the Belleville washer. This seemingly simple, conical disc-shaped spring packs an impressive punch, delivering a surprising amount of force and providing vital support for various applications. From clamping down bolts to ensuring consistent pressure in pressure-sensitive devices, Belleville washers are indispensable for ensuring optimal performance and durability.

Imagine a small, conical disc, its edges curving inward, crafted from hardened steel. This, in essence, is a Belleville washer. While its name may sound like something out of a fantasy novel, its function is anything but fantastical. These washers are engineered to be highly resilient and capable of generating significant force when compressed, acting as miniature springs that withstand immense pressure.

One of the defining features of Belleville washers is their ability to exert a consistent clamping force. Unlike conventional flat washers, which merely distribute the load evenly, Belleville washers can create a powerful and reliable pre-load on bolted connections. This pre-load ensures that components remain tightly secured even under extreme conditions, preventing loosening, vibration, and potential failures.

The unique geometry of Belleville washers allows for controlled deflection, providing a range of spring rates. By adjusting the thickness, diameter, and cone angle, engineers can fine-tune the amount of force generated for specific applications. This versatility makes them ideal for a wide range of industries, including automotive, aerospace, and industrial machinery.

Beyond their remarkable strength, Belleville washers are also prized for their reliability and longevity. They are designed to endure countless cycles of compression and release without significant degradation, ensuring long-term performance and minimal maintenance requirements.

The applications of Belleville washers are as diverse as the industries they serve. Let's explore some of their key roles:

Belleville washers are widely used in bolt clamping applications, where their ability to generate significant pre-load is essential. Imagine a scenario where a bolted joint is subjected to vibration or temperature fluctuations. Without adequate pre-load, the bolts may loosen, leading to component failure. Belleville washers, acting as miniature springs, provide the necessary force to counteract these factors and maintain a secure connection.

The precision spring rate of Belleville washers makes them perfect for applications requiring consistent pressure, such as pressure-sensitive switches, clutches, and brakes. By controlling the amount of force needed to activate these devices, Belleville washers ensure accurate and reliable operation, crucial for safety and performance.

Belleville washers can also act as shock absorbers and vibration dampeners. Their inherent spring characteristics allow them to absorb sudden impacts and dissipate energy, protecting delicate components from damage. This is particularly important in applications involving heavy machinery, transportation systems, and sensitive instruments.

Beyond their common applications, Belleville washers are utilized in specialized situations, such as:

Selecting the appropriate Belleville washer for a particular application requires careful consideration of several factors, including:

Consulting with experienced engineers or manufacturers specializing in Belleville washers can help ensure optimal selection for your specific needs.

Belleville washers may seem like small, unremarkable components, but their impact on mechanical systems is undeniable. From ensuring the strength of bolted connections to providing consistent pressure in sensitive devices, these humble springs play a crucial role in ensuring optimal performance and durability. Their versatility, reliability, and ability to withstand demanding environments make them invaluable assets in a wide range of applications.

So the next time you encounter a Belleville washer, don't dismiss it as just another washer. It's a testament to ingenuity and precision engineering, a tiny force of nature that holds immense power. They are the unsung heroes of mechanical strength, ensuring the integrity and longevity of countless devices across diverse industries.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.