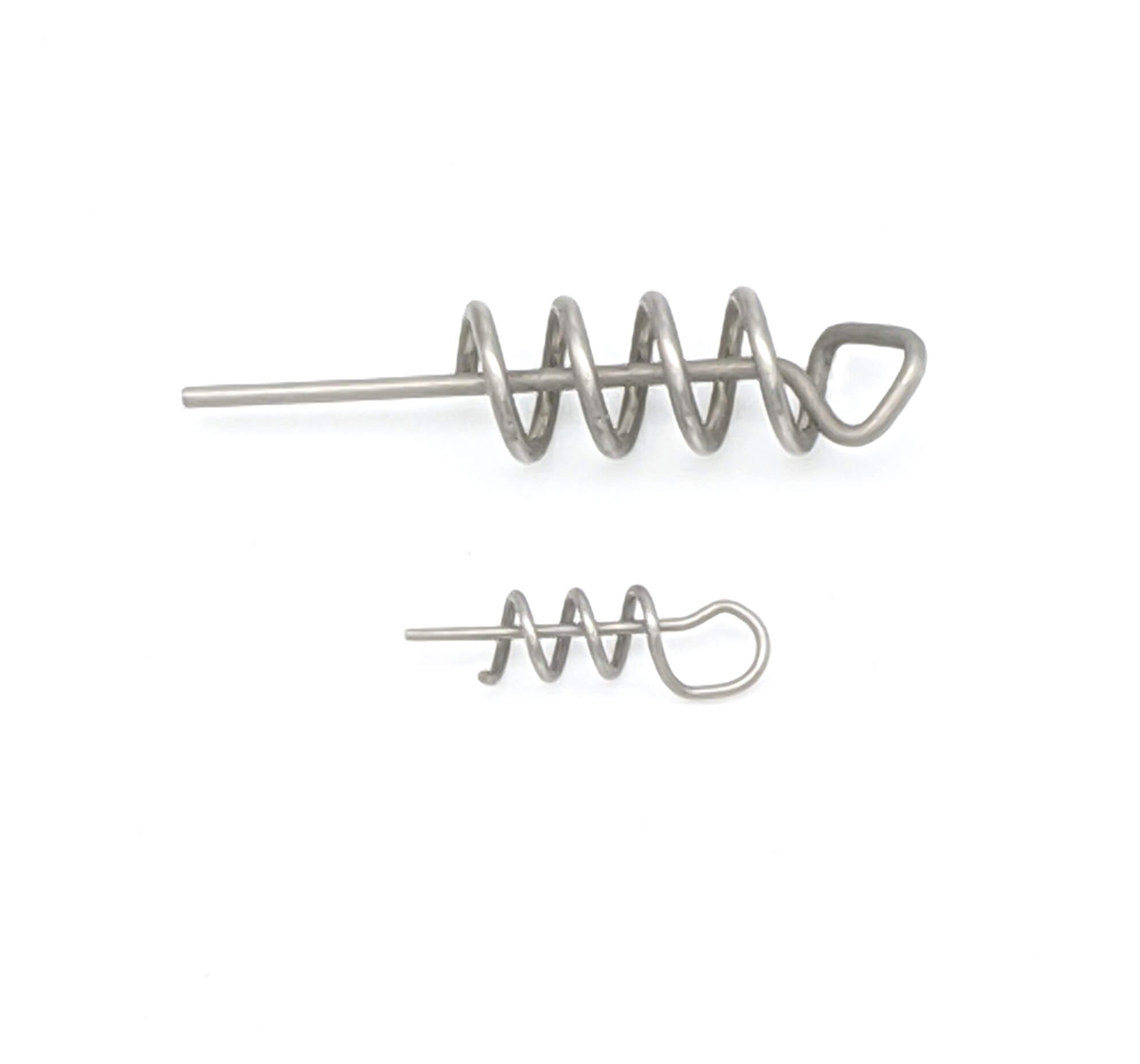

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Imagine a tiny, seemingly insignificant disc of metal that can hold the immense weight of a truck or the delicate pressure of a surgical instrument. That's the power of the

Imagine a tiny, seemingly insignificant disc of metal that can hold the immense weight of a truck or the delicate pressure of a surgical instrument. That's the power of the Belleville washer, a deceptively simple yet remarkably versatile spring element that plays a crucial role in countless mechanical applications. From heavy-duty machinery to precision instruments, Belleville washers quietly work behind the scenes, providing essential clamping force, preloading, and load distribution.

A Belleville washer, also known as a conical spring washer, is a disc-shaped spring with a conical or dish-shaped profile. It's essentially a spring formed by bending a flat piece of metal into a curved shape, creating a distinct concave-convex design. The key to its effectiveness lies in this unique geometry, which allows it to store and release energy as it flexes under load.

Belleville washers function based on a principle of elastic deformation. When a load is applied to the washer, it deflects inwards, storing energy. This stored energy translates into a reactive force that counteracts the applied load. What sets Belleville washers apart is their ability to generate substantial force even with relatively small deflections, making them extremely efficient in managing loads and achieving precise clamping forces.

The unique design of Belleville washers offers a range of advantages that make them ideal for numerous applications:

The versatility and effectiveness of Belleville washers make them indispensable components across a wide range of industries and applications:

Belleville washers are extensively used in the automotive industry, playing a critical role in various components, including:

The demanding requirements of aerospace applications necessitate high-performance components like Belleville washers. They are used in:

Belleville washers are essential components in a wide range of industrial machinery, including:

The precision and reliability of Belleville washers make them suitable for use in medical devices:

Beyond these major industries, Belleville washers find their way into countless other applications, including:

Selecting the appropriate Belleville washer for a specific application requires careful consideration of various factors, including:

Belleville washers, though seemingly simple, are powerful and versatile components that play a crucial role in countless mechanical systems. Their ability to provide consistent force, manage high loads, and adapt to diverse applications makes them indispensable for engineers and designers across a wide range of industries. So, the next time you encounter a seemingly insignificant disc of metal, remember the remarkable potential of the humble Belleville washer, quietly working behind the scenes to ensure smooth and reliable operation of the systems we depend on every day.

Belleville washers are a testament to the beauty and ingenuity of mechanical engineering. They are an excellent example of how seemingly simple designs can deliver incredible functionality, serving as the unsung heroes of countless mechanical systems. Their versatility, high load capacity, and constant force make them essential components for everything from heavy-duty machinery to delicate medical instruments. So, the next time you encounter a Belleville washer, take a moment to appreciate the intricate design and the crucial role it plays in keeping our world running smoothly.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.