Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the world of mechanical engineering, back coil springs are often overlooked, yet they play a crucial role in countless applications. These seemingly simple components, characterized by their unique design

In the world of mechanical engineering, back coil springs are often overlooked, yet they play a crucial role in countless applications. These seemingly simple components, characterized by their unique design and functionality, are essential for providing support, control, and stability in a wide range of systems. From automotive suspensions to precision instruments, back coil springs are quietly working behind the scenes to ensure smooth operation and prevent unwanted movement. This article delves into the fascinating world of back coil springs, exploring their construction, properties, and diverse applications, highlighting their often-unsung contributions to the world of engineering.

Back coil springs, also known as compression springs with a back coil, are a type of helical spring designed to resist compression forces. Unlike standard compression springs, back coil springs feature an additional coil at the end that acts as a stop, preventing the spring from collapsing entirely. This back coil, often referred to as a 'solid height,' determines the spring's minimum compressed length, ensuring that it always maintains a certain level of support.

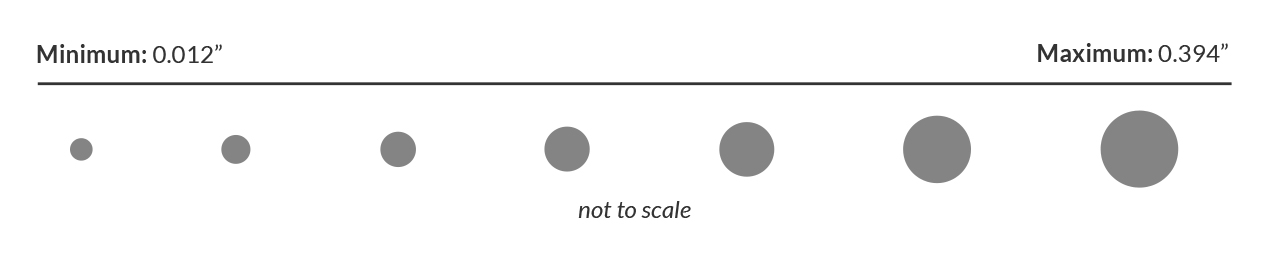

Back coil springs are typically made from spring steel wire, chosen for its high tensile strength and elasticity. The wire is wound into a helical coil, with the back coil being formed at the end. The diameter of the wire, the number of coils, and the spring index (ratio of coil diameter to wire diameter) all influence the spring's stiffness and load capacity.

Back coil springs offer several distinct advantages over traditional compression springs, making them ideal for a wide range of applications:

Back coil springs are employed in countless applications, spanning a wide range of industries:

Selecting the correct back coil spring for a specific application requires careful consideration of several factors, including:

Back coil springs are often the unsung heroes of mechanical design, playing a crucial role in countless applications. Their unique construction and properties make them ideal for providing support, control, and stability in a wide range of systems. By understanding the advantages and applications of back coil springs, engineers can choose the most appropriate solution for their specific needs, ensuring optimal performance and longevity for their designs.

As we've explored, back coil springs offer an impressive combination of strength, durability, and control, making them essential components in various industries. Their understated presence belies their vital role in ensuring the smooth and reliable operation of countless systems. So next time you encounter a mechanical system, remember to appreciate the silent workhorses - the back coil springs - diligently contributing to its performance and stability.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.