Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Arc springs, also known as pre-curved helical compression springs, offer a unique and valuable solution in various mechanical engineering applications. Their distinctive design, characterized by a pre-curved or arc-shaped coil,

Arc springs, also known as pre-curved helical compression springs, offer a unique and valuable solution in various mechanical engineering applications. Their distinctive design, characterized by a pre-curved or arc-shaped coil, enables them to transmit torque around an axis, setting them apart from conventional helical springs. This article delves into the world of arc springs, exploring their construction, advantages, applications, and the factors to consider when selecting the right arc spring for a particular task.

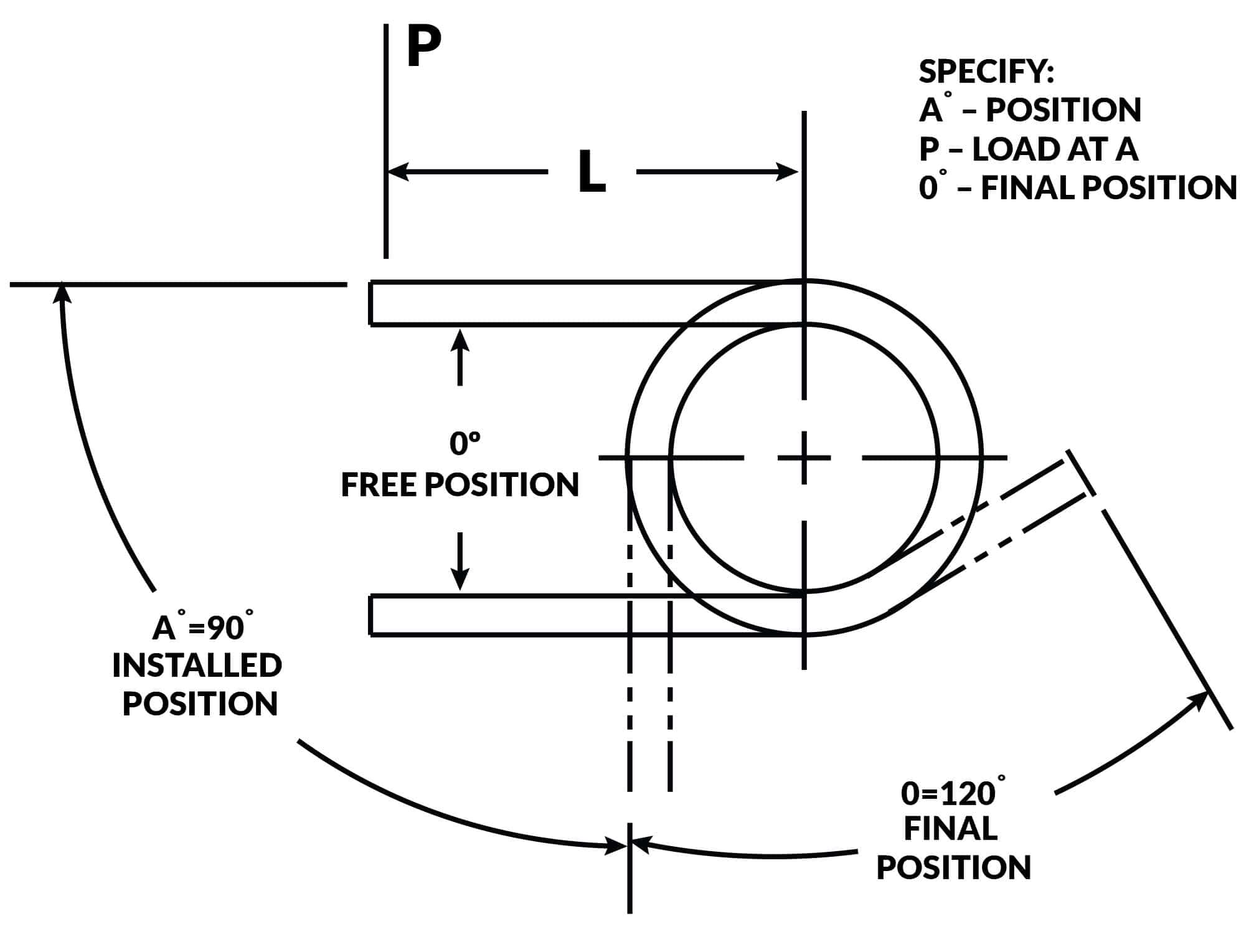

Arc springs are a specialized type of helical compression spring, distinguished by their pre-curved or arc-shaped coil. This unique geometry allows them to transmit torque around an axis, a feature not found in standard helical springs. The arc shape provides a significant advantage in applications where rotational force is required, making them a valuable tool for engineers seeking efficient and reliable torque transmission.

To grasp the intricacies of arc springs, it's essential to understand their construction. They are typically made from high-quality spring steel, which is coiled and then bent into the desired arc shape. The degree of curvature, wire diameter, and material properties all influence the spring's characteristics, such as its spring rate and torque capacity.

Arc springs offer several advantages that make them attractive to engineers working on a variety of projects. Here are some of their key strengths:

1. **Efficient Torque Transmission:** Their pre-curved design allows them to effectively transmit torque around an axis, making them ideal for applications requiring rotational force. This capability distinguishes them from conventional helical springs, which primarily handle compression forces.

2. **Compact Size:** Arc springs can be designed to be compact, saving space in tight applications. Their ability to transmit torque efficiently allows for a smaller footprint compared to other torque-transmitting solutions.

3. **High Load Capacity:** Arc springs are capable of handling significant loads, making them suitable for demanding applications. The strength of the spring steel used in their construction contributes to their impressive load capacity.

4. **Long Service Life:** Due to the robust nature of their materials and design, arc springs boast a long service life, making them a reliable choice for applications where durability is crucial.

5. **Versatile Applications:** Arc springs find applications across a wide range of industries and fields, showcasing their adaptability to diverse mechanical engineering needs.

Arc springs are versatile and find applications in various industries and engineering fields. Here are some notable examples:

1. **Automotive Industry:** Arc springs are frequently used in automotive applications, such as power steering systems, suspension systems, and brake systems. Their ability to transmit torque efficiently and withstand high loads makes them ideal for these demanding applications.

2. **Aerospace Industry:** The aerospace industry relies on arc springs for various components, including landing gear systems, control surfaces, and actuators. Their compact size, high load capacity, and reliability make them suitable for critical aerospace applications.

3. **Industrial Machinery:** Arc springs play a vital role in industrial machinery, finding use in clutches, brakes, and other torque-transmitting components. Their durability and ability to handle heavy loads make them well-suited for these demanding environments.

4. **Medical Devices:** Arc springs can be found in medical devices, such as surgical instruments, prosthetic limbs, and medical imaging equipment. Their precise force control and reliability are crucial in these sensitive applications.

5. **Consumer Products:** Arc springs also find their way into consumer products, such as door hinges, spring-loaded mechanisms in retractable pens, and other applications where compact and efficient torque transmission is required.

When selecting an arc spring for a particular application, several factors need careful consideration to ensure optimal performance and longevity. These factors include:

1. **Spring Rate:** The spring rate determines the amount of force required to compress the spring a specific distance. The spring rate should be chosen based on the load and deflection requirements of the application.

2. **Torque Capacity:** The torque capacity of the spring is the maximum amount of torque it can handle without permanent deformation. It's essential to choose a spring with sufficient torque capacity to meet the demands of the application.

3. **Material Selection:** The material used for the arc spring significantly impacts its strength, durability, and resistance to corrosion. Choosing the right material is crucial for ensuring the spring's longevity and performance.

4. **Wire Diameter:** The diameter of the spring wire affects its strength and flexibility. A thicker wire results in a stronger spring, while a thinner wire provides more flexibility. The appropriate wire diameter should be chosen based on the load and deflection requirements.

5. **Arc Shape:** The shape of the arc influences the spring's force characteristics. A tighter arc generally results in a higher spring rate and a lower torque capacity.

6. **Environmental Conditions:** Consider the operating environment where the spring will be used. Factors such as temperature, humidity, and exposure to chemicals can affect the spring's performance and lifespan. Choose a spring made from a material that can withstand the environmental conditions.

Arc springs are a versatile and powerful component in mechanical engineering, offering advantages such as efficient torque transmission, compact size, high load capacity, and long service life. They are a valuable tool for engineers across various industries and fields, finding applications in automotive systems, aerospace components, industrial machinery, medical devices, and consumer products. When selecting an arc spring, it's essential to consider factors such as spring rate, torque capacity, material selection, wire diameter, arc shape, and environmental conditions to ensure optimal performance and longevity.

Arc springs offer a compelling solution for engineers seeking reliable torque transmission, compact design, and robust performance. Their versatility and adaptability make them a valuable asset across various applications. By understanding their advantages, applications, and selection criteria, engineers can harness the power of arc springs to create innovative and efficient mechanical systems.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.