Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

1-inch diameter compression springs are a staple in countless industrial and consumer applications. These robust and versatile components play a crucial role in everything from automotive suspension systems to delicate

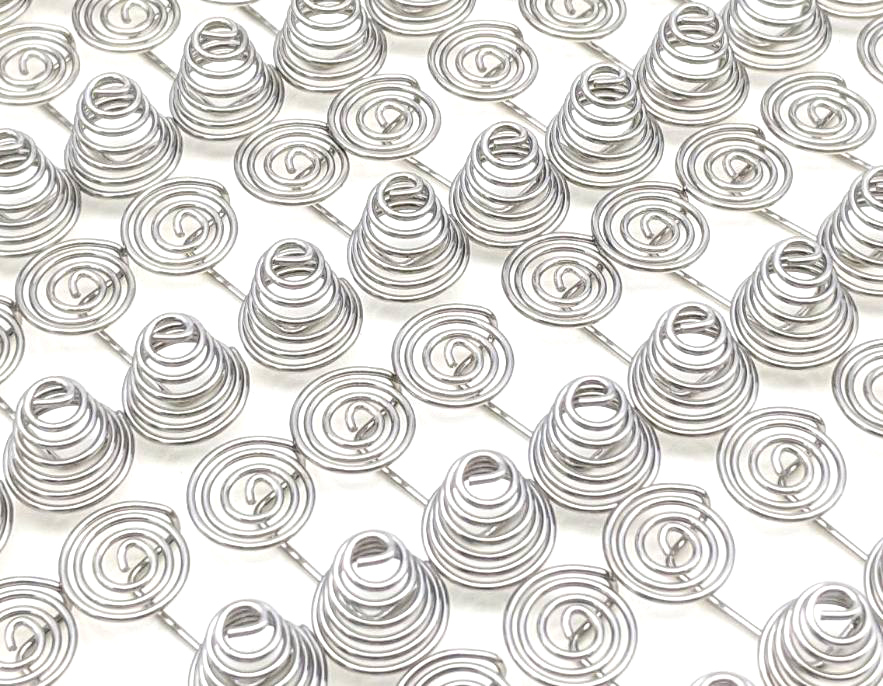

1-inch diameter compression springs are a staple in countless industrial and consumer applications. These robust and versatile components play a crucial role in everything from automotive suspension systems to delicate medical devices. In this comprehensive guide, we delve into the world of 1-inch diameter compression springs, exploring their design, materials, properties, and applications. We'll also discuss factors to consider when selecting the right spring for your specific needs, making sure you have all the information you need to make informed decisions.

Compression springs, as the name suggests, are designed to resist compressive forces. They are typically helical in shape, consisting of tightly wound coils of wire. When a load is applied to a compression spring, it compresses, storing energy. This energy is then released when the load is removed, causing the spring to return to its original length. 1-inch diameter compression springs, with their relatively large size, are often used in applications requiring high force or significant displacement.

The design of a compression spring is crucial to its performance. Key parameters include the wire diameter, the coil diameter, the number of coils, and the material used. These factors determine the spring's stiffness, which is a measure of how much force is required to compress it a given distance.

The choice of material for a 1-inch diameter compression spring depends on the application's specific requirements.

**Spring Steel:** This is the most common material for compression springs due to its excellent strength, durability, and resilience.

**Stainless Steel:** When corrosion resistance is a priority, stainless steel is often chosen. It can withstand harsh environments and is ideal for applications exposed to moisture, chemicals, or extreme temperatures.

**Phosphor Bronze:** This material provides excellent corrosion resistance and electrical conductivity. It is commonly used in applications where these properties are critical, such as in electrical contacts.

**Beryllium Copper:** Known for its high strength and electrical conductivity, beryllium copper is often employed in springs that must carry electrical currents. However, it is also more expensive than other materials.

Understanding the properties of 1-inch diameter compression springs is essential for selecting the right one for your application.

**Spring Rate:** This is a measure of the spring's stiffness, expressed in units of force per unit of deflection. It determines how much force is required to compress the spring a specific distance. A higher spring rate indicates a stiffer spring.

**Spring Force:** This is the force the spring exerts when it is compressed. It is directly proportional to the spring rate and the deflection.

**Deflection:** This is the amount of compression the spring undergoes under a given load.

**Solid Height:** This is the minimum height the spring can be compressed to before the coils touch.

**Free Length:** This is the length of the spring when it is uncompressed.

**Fatigue Life:** This is a measure of the spring's resistance to repeated compression and release cycles.

1-inch diameter compression springs are found in a wide range of applications, including:

**Automotive:**

**Industrial:**

**Consumer Products:**

**Medical Devices:**

**Aerospace:**

Choosing the right 1-inch diameter compression spring for your application requires careful consideration of several factors.

**Load:** Determine the maximum force the spring will be subjected to.

**Deflection:** How much compression is required to achieve the desired function?

**Space Constraints:** What is the available space for the spring?

**Material Requirements:** Consider corrosion resistance, electrical conductivity, and temperature requirements.

**Fatigue Life:** How many cycles will the spring need to endure?

**Cost:** Compare prices from different suppliers and consider the trade-off between price and performance.

1-inch diameter compression springs are essential components in countless industries. Understanding their design, materials, properties, and applications is crucial for selecting the right spring for your specific needs. By carefully considering the factors discussed above, you can ensure optimal performance and reliability in your applications.

From automotive suspension systems to medical devices, 1-inch diameter compression springs play a vital role in countless applications. By understanding their design, materials, properties, and applications, you can make informed decisions and select the right spring to meet your specific requirements. Always remember to consider factors like load, deflection, space constraints, material requirements, fatigue life, and cost for optimal performance and reliability. With the right spring, you can ensure the smooth and efficient operation of your systems.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.