Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Tiny tension springs, often overlooked and underestimated, play a crucial role in countless applications, providing a powerful force in miniature. These resilient and reliable components are found everywhere, from delicate

Tiny tension springs, often overlooked and underestimated, play a crucial role in countless applications, providing a powerful force in miniature. These resilient and reliable components are found everywhere, from delicate electronics to robust industrial machinery, quietly ensuring smooth operation and precise performance. In this article, we'll delve into the world of tiny tension springs, exploring their unique characteristics, diverse applications, and the remarkable impact they have on our everyday lives.

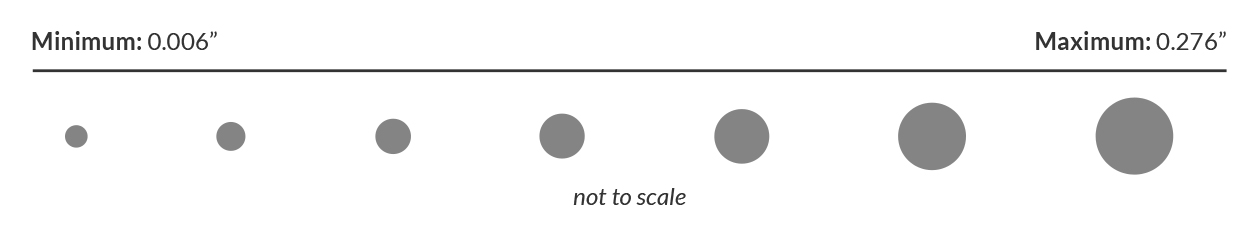

Tiny tension springs are essentially miniaturized versions of their larger counterparts, offering similar functionality but on a much smaller scale. They are typically made from high-quality spring steel wire, meticulously coiled into a helical shape. This design imparts a unique elasticity, allowing the spring to absorb and release energy with remarkable efficiency. What sets tiny tension springs apart is their ability to generate substantial force despite their diminutive size.

Their compact dimensions allow for seamless integration into tight spaces, making them ideal for applications where space is a premium. Imagine the intricate workings of a smartphone, where tiny tension springs provide the necessary force for button activation or camera lens movement. This same principle applies to a wide range of devices, from medical instruments to automotive components, where precision and reliability are paramount.

The diverse applications of tiny tension springs are truly astonishing. They are ubiquitous in various industries, proving their versatility and indispensable nature. Let's explore some of the key areas where these miniature marvels shine:

1. Electronics and Consumer Products: Tiny tension springs are integral to the functionality of countless electronic devices. From the delicate springs that provide tactile feedback in smartphone buttons to the springs that keep the internal components of a laptop securely in place, they ensure smooth operation and prevent wear and tear.

2. Automotive Industry: In the world of automobiles, tiny tension springs play a vital role in various components. They provide the necessary tension for door latches, window regulators, and even the intricate mechanisms of seatbelt retractors. Their reliability is critical for passenger safety and overall vehicle performance.

3. Medical Devices: The medical field relies heavily on the precision and reliability of tiny tension springs. They are employed in surgical instruments, medical implants, and diagnostic devices, ensuring smooth operation and precise control in delicate procedures.

4. Aerospace and Defense: Even in the demanding world of aerospace and defense, tiny tension springs find their place. Their ability to withstand extreme temperatures, vibrations, and corrosive environments makes them ideal for critical components in aircraft, satellites, and military equipment.

5. Industrial Machinery: In industrial settings, where heavy machinery operates under demanding conditions, tiny tension springs contribute to smooth operation and reduced wear. They provide the necessary force for clutches, brakes, and other critical components, ensuring uninterrupted productivity.

The popularity of tiny tension springs stems from their numerous advantages, which make them a preferred choice for various applications:

1. Compact Size and Lightweight Design: Tiny tension springs are remarkably compact, allowing for their seamless integration into tight spaces. Their lightweight nature minimizes added weight and ensures efficient operation.

2. High Strength-to-Weight Ratio: Despite their small size, tiny tension springs possess remarkable strength. Their high strength-to-weight ratio enables them to generate significant force while remaining lightweight and compact.

3. Resilience and Durability: Tiny tension springs are designed to withstand repeated cycles of compression and extension, making them highly resilient and durable. They can operate effectively for extended periods without experiencing significant wear or degradation.

4. Versatility and Customization: Tiny tension springs can be manufactured in various materials, sizes, and configurations to meet specific application requirements. This versatility allows engineers to customize them for optimal performance in different environments.

5. Cost-Effectiveness: Tiny tension springs are generally cost-effective, making them an attractive option for various applications. Their low cost combined with high performance makes them a viable choice for manufacturers across industries.

As technology advances, the demand for tiny tension springs is expected to grow. Advancements in manufacturing techniques and material science are continually pushing the boundaries of what these miniature components can achieve. Here are some key trends shaping the future of tiny tension springs:

1. Miniaturization: The relentless pursuit of miniaturization in electronics and other industries will drive the demand for even smaller and more precise tiny tension springs. Advanced manufacturing processes, such as micro-machining and laser cutting, are paving the way for ultra-compact designs.

2. Smart Materials: The development of smart materials, such as shape memory alloys and piezoelectrics, is opening up new possibilities for tiny tension springs. These materials can adapt to changing conditions, providing enhanced functionality and performance.

3. Sustainable Manufacturing: The growing emphasis on sustainability is influencing the manufacturing processes of tiny tension springs. Manufacturers are embracing eco-friendly materials and energy-efficient production methods to reduce their environmental footprint.

Tiny tension springs, often unseen and unappreciated, play a critical role in our modern world. Their ability to provide powerful force in miniature has revolutionized countless industries and products. From the smartphones we use daily to the medical devices that save lives, tiny tension springs quietly ensure smooth operation, precision, and reliability. As technology continues to advance, these miniature marvels will undoubtedly continue to shape our world, contributing to innovative solutions and improving our lives in countless ways.

Tiny tension springs are a testament to the power of ingenuity and precision engineering. Their small size belies their remarkable strength and versatility, making them essential components in countless applications. As we continue to explore the boundaries of miniaturization and innovation, tiny tension springs will undoubtedly play an even more significant role in shaping our future. From the delicate workings of smartphones to the sophisticated mechanisms of advanced medical devices, these miniature marvels quietly ensure smooth operation, precision, and reliability, contributing to a world where technology seamlessly enhances our lives.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.