Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the world of mechanical engineering, springs play a crucial role in countless applications, from simple door hinges to complex automotive systems. Two common types of springs are tension springs

In the world of mechanical engineering, springs play a crucial role in countless applications, from simple door hinges to complex automotive systems. Two common types of springs are tension springs and torsion springs, each designed to handle forces in different ways. While they might look similar at first glance, understanding the key distinctions between these two spring types is essential for choosing the right one for your specific needs.

Tension springs, also known as extension springs, are designed to withstand pulling forces. Imagine a rubber band; when you stretch it, it's acting like a tension spring. These springs are typically coiled with the turns touching in their relaxed state. When you apply a force to pull the ends apart, the spring extends, storing potential energy. The more you stretch it, the greater the force it exerts to return to its original length.

Tension springs are ubiquitous in everyday objects and industrial equipment. Here are some common examples:

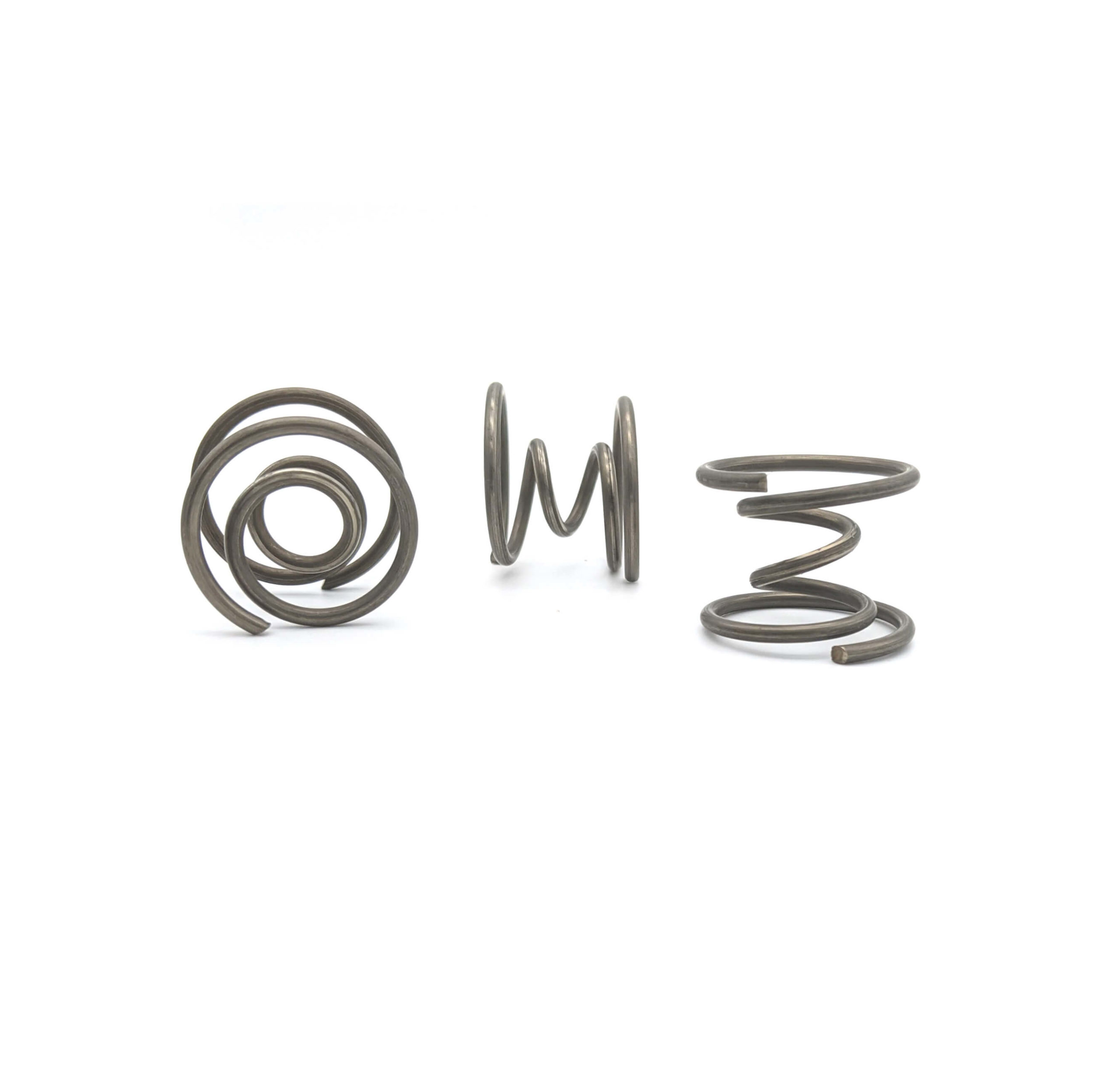

Torsion springs, on the other hand, are built to handle twisting forces. Think of a spring-loaded clothespin; when you squeeze it, you're applying torsion to the spring. Torsion springs are often coiled in a spiral or helical shape. Applying a twisting force (torque) to the spring causes it to wind up or unwind, storing energy in the process.

Torsion springs find their way into a variety of applications, often where rotational motion is involved.

While both tension and torsion springs are essential components in many applications, they have distinct features and characteristics. Here's a table summarizing the key differences:

| Feature | Tension Spring | Torsion Spring |

|---|---|---|

| Load Type | Tension (pulling force) | Torque (twisting force) |

| Movement | Extends/contracts | Twists/rotates |

| Typical Shape | Coiled with turns touching | Spiral or helical coil |

| Energy Storage | Stored by stretching | Stored by twisting |

| Common Applications | Door closers, clotheslines, mechanical pencils | Clocks, steering wheels, clamps |

Selecting the appropriate spring type for your project is crucial for its proper function and longevity. Here are some factors to consider when deciding between tension and torsion springs:

Consulting with a spring specialist or engineer can provide valuable guidance for choosing the most suitable spring type for your specific needs. They can help you determine the optimal size, material, and configuration for your application, ensuring the spring performs reliably and safely.

Tension springs and torsion springs are essential mechanical components found in countless applications. By understanding their unique properties and applications, engineers and designers can choose the right spring to achieve optimal performance and reliability. From simple door closers to complex automotive systems, springs continue to play a vital role in our daily lives, often working quietly behind the scenes to make our world function smoothly.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.