Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

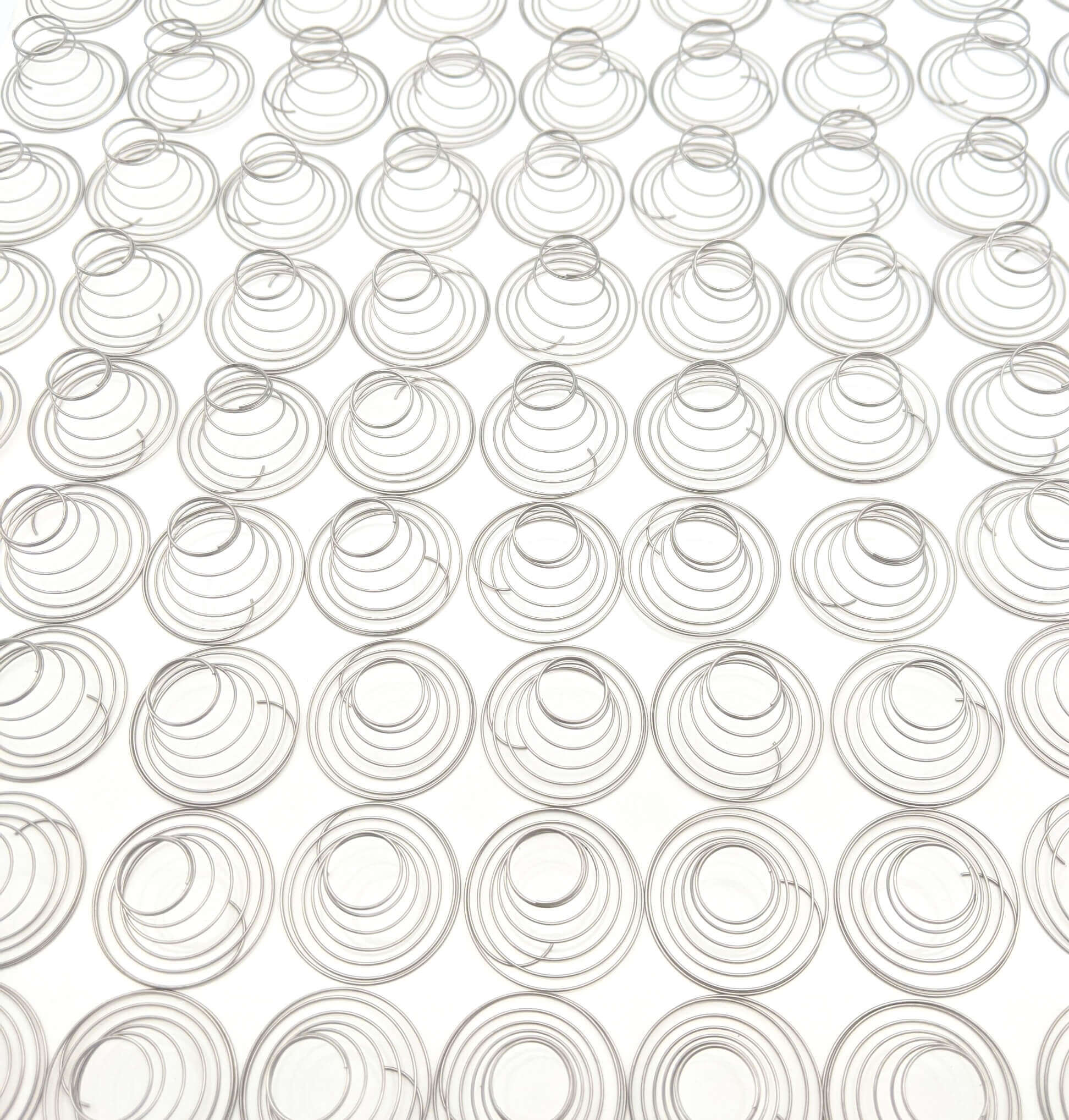

Stainless steel compression springs are a highly sought-after solution for a wide range of industries, from automotive and aerospace to medical and consumer products. Their inherent resilience and resistance to

Stainless steel compression springs are a highly sought-after solution for a wide range of industries, from automotive and aerospace to medical and consumer products. Their inherent resilience and resistance to corrosion make them ideal for demanding applications where reliability and long-lasting performance are crucial. In this comprehensive guide, we'll delve into the world of stainless compression springs, exploring their advantages, applications, and factors to consider when choosing the right spring for your specific needs.

Stainless steel compression springs offer a unique blend of strength, durability, and corrosion resistance, making them a preferred choice for various demanding applications. These springs are engineered to withstand extreme conditions, including high temperatures, harsh chemicals, and fluctuating environments, ensuring they maintain their structural integrity and performance over time.

The superior qualities of stainless steel compression springs stem from their inherent properties. Let's explore the key benefits that make them stand out:

The versatility of stainless steel compression springs makes them valuable assets across a wide range of industries. Let's take a look at some prominent applications:

Selecting the appropriate stainless steel compression spring for your application requires careful consideration of several factors. Here's a comprehensive guide to help you make the right choice:

To maximize the lifespan and performance of stainless steel compression springs, it's essential to follow these maintenance practices:

Stainless steel compression springs are a testament to the power of precision engineering. Their exceptional strength, corrosion resistance, and adaptability make them indispensable in various industries. By understanding the benefits, applications, and factors to consider when selecting the right spring, you can ensure optimal performance and longevity for your applications. Remember, choosing a high-quality stainless steel compression spring is an investment in long-term reliability and performance, ensuring your projects succeed.

Stainless steel compression springs embody the perfect blend of strength, resilience, and versatility. They are a crucial component in numerous industries, from automotive and aerospace to medical and consumer goods. By understanding their benefits, applications, and selection considerations, you can harness their power to enhance the performance and reliability of your projects, setting the stage for long-lasting success.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.