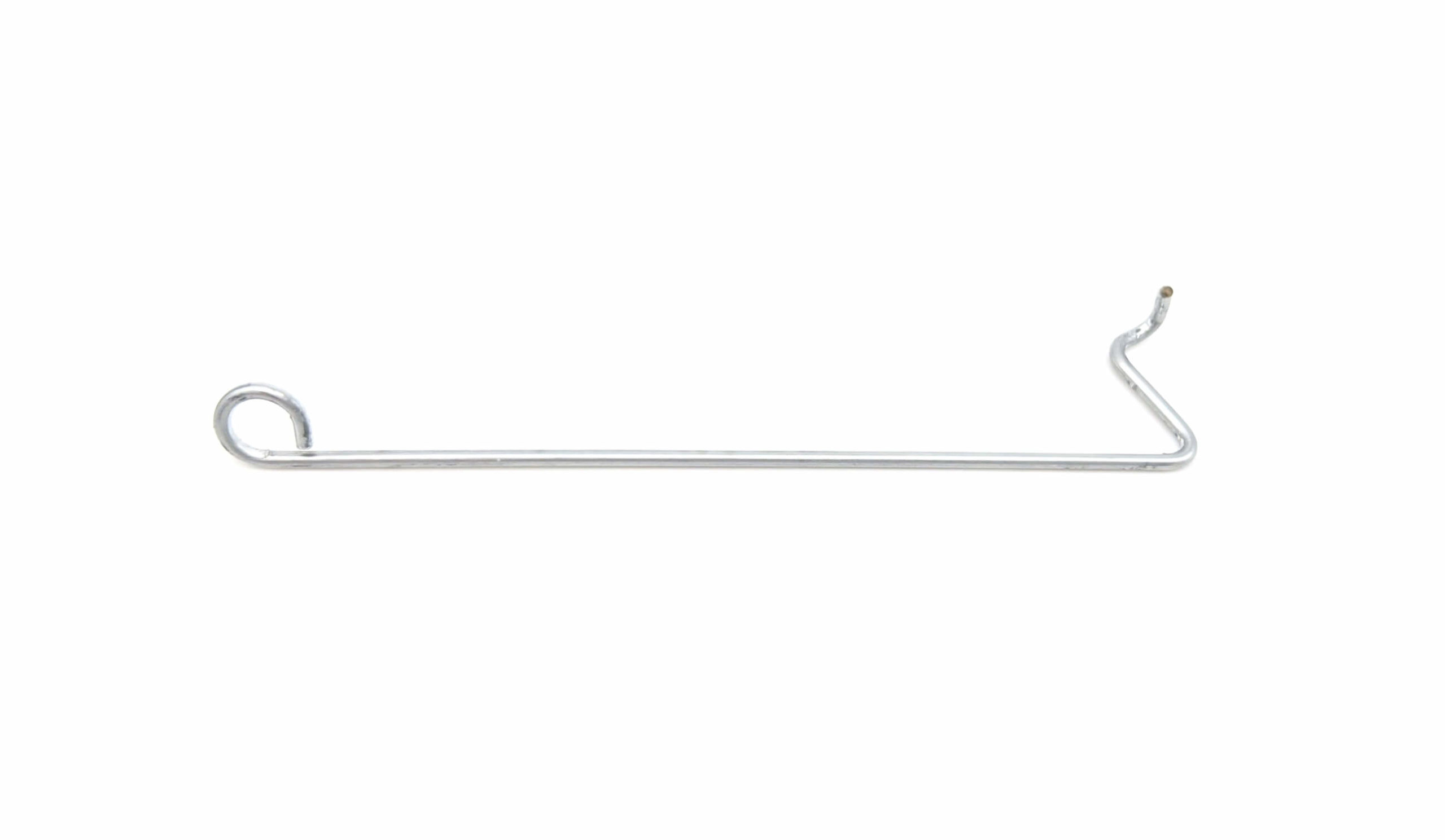

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Stainless steel compression springs are ubiquitous components found in countless applications, from aerospace and automotive to medical devices and consumer products. Their resilience, corrosion resistance, and versatility make them indispensable

Stainless steel compression springs are ubiquitous components found in countless applications, from aerospace and automotive to medical devices and consumer products. Their resilience, corrosion resistance, and versatility make them indispensable for engineers and designers seeking reliable and long-lasting spring solutions. This comprehensive guide delves into the world of stainless steel compression springs, exploring their properties, types, applications, selection criteria, and maintenance tips. Whether you're an engineer seeking the perfect spring for your next project or simply curious about these essential mechanical components, this guide has something for you.

Compression springs are open-coil helical springs designed to resist linear compression. When a force is applied, the spring compresses, storing potential energy. Upon release of the force, the spring expands back to its original length, releasing the stored energy. This simple yet effective mechanism finds application in a wide range of devices and machinery.

Stainless steel stands out as a preferred material for compression springs due to its exceptional properties. Let's explore some of the key reasons:

Corrosion Resistance: Stainless steel's inherent resistance to rust and corrosion makes it ideal for applications exposed to moisture, chemicals, and harsh environments. This ensures long-term performance and reduces maintenance requirements.

Strength and Durability: Stainless steel exhibits excellent tensile strength and fatigue resistance, enabling springs to withstand repeated compression cycles without failure. This durability is crucial for applications demanding reliability and extended service life.

Temperature Resistance: Certain grades of stainless steel can withstand high temperatures without significant loss of strength or degradation. This makes them suitable for applications involving extreme heat, such as engine components and industrial machinery.

Hygiene and Cleanliness: Stainless steel's smooth, non-porous surface prevents the accumulation of dirt, bacteria, and other contaminants. This makes it suitable for applications demanding hygiene, such as medical devices and food processing equipment.

Various grades of stainless steel are used for compression springs, each offering a unique set of properties tailored to specific applications. Here are some commonly used grades:

302 Stainless Steel: A general-purpose stainless steel with good corrosion resistance and strength. It's suitable for a wide range of applications.

316 Stainless Steel: Known for its enhanced corrosion resistance, particularly against chlorides and acids, making it suitable for marine and chemical processing applications.

17-7 PH Stainless Steel: Offers high strength and excellent fatigue resistance, making it suitable for demanding applications requiring long-lasting performance.

The versatility of stainless steel compression springs is evident in their wide array of applications, spanning numerous industries:

Aerospace: Springs for landing gear, control systems, and engine components.

Automotive: Springs for suspension systems, valves, and braking systems.

Medical: Springs for surgical instruments, medical implants, and diagnostic equipment.

Industrial: Springs for manufacturing machinery, pumps, and valves.

Consumer Products: Springs for appliances, electronics, and toys.

Choosing the optimal stainless steel compression spring for your application involves considering several factors:

Load Requirements: Determine the maximum force the spring needs to withstand and its expected compression range.

Environmental Conditions: Consider the temperature, humidity, and presence of corrosive agents to select a suitable stainless steel grade.

Space Constraints: Measure the available space for the spring, including its diameter, length, and end configurations.

Durability Needs: Evaluate the expected lifespan and the number of compression cycles the spring will undergo to select a grade with adequate fatigue resistance.

Proper maintenance can extend the lifespan of stainless steel compression springs. Here are some tips:

Cleanliness: Regularly remove dirt, debris, and corrosive substances from the spring's surface.

Lubrication: Apply a suitable lubricant to reduce friction and wear, especially in high-cycle applications.

Inspection: Periodically inspect the spring for signs of damage, corrosion, or wear. Replace damaged springs promptly to prevent system failures.

Stainless steel compression springs are indispensable components in countless applications, offering a remarkable combination of strength, corrosion resistance, and versatility. By understanding their properties, types, applications, selection criteria, and maintenance practices, engineers and designers can harness their full potential to create robust, reliable, and long-lasting products. From everyday consumer goods to advanced aerospace systems, stainless steel compression springs play a vital role in shaping our technological world.

Stainless steel compression springs are the unsung heroes of countless machines and devices, providing reliable performance and enduring strength. Their versatility and adaptability make them essential components across various industries. Whether you're an engineer designing complex machinery or simply appreciate the ingenuity of these small yet mighty springs, understanding their significance and characteristics enhances our appreciation for the intricate workings of our technological world.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.