Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Small compression springs, despite their diminutive size, pack a punch in mechanical systems. These coiled marvels, often overlooked, are essential components that provide force, support, and energy storage. From delicate

Small compression springs, despite their diminutive size, pack a punch in mechanical systems. These coiled marvels, often overlooked, are essential components that provide force, support, and energy storage. From delicate electronics to powerful machinery, small compression springs are found in countless applications, silently performing their critical functions. Their ability to store and release energy, absorb shocks, and maintain constant pressure makes them indispensable in a wide range of industries.

The beauty of small compression springs lies in their ability to deliver significant force and energy within a compact package. They are typically made from high-strength materials like steel, stainless steel, or spring wire, and are designed to compress under load, storing potential energy. This energy is then released when the spring returns to its original shape, providing a force that can be used to perform a variety of tasks.

Their small size and impressive force-to-size ratio make them ideal for applications where space is limited, such as in electronic devices, medical equipment, and precision instruments. A small compression spring can be found in everything from a ballpoint pen to a smartphone, providing the reliable force needed for smooth operation and a positive feel.

The versatility of small compression springs is reflected in their wide range of applications, spanning across various industries. Let's take a look at some key areas where these tiny powerhouses shine:

• **Electronics:** Small compression springs play a crucial role in electronic devices by providing contact pressure for switches, buttons, and connectors. They ensure reliable electrical connections, ensuring smooth and consistent operation.

• **Medical Devices:** In healthcare, small compression springs are used in a multitude of devices, including surgical instruments, catheters, and prosthetic limbs. Their biocompatibility and reliability make them ideal for delicate procedures and patient safety.

• **Automotive:** Cars and trucks are filled with small compression springs that perform vital functions. They are used in seat adjustments, door latches, and engine components, contributing to the vehicle's overall performance and comfort.

• **Aerospace:** Small compression springs are even found in aerospace applications, where their lightweight design and high-strength materials are essential for aircraft components and satellites. They provide reliable support, tension, and shock absorption in demanding environments.

• **Consumer Products:** From toys to appliances, small compression springs are ubiquitous in consumer goods. They provide the 'snap' in retractable pens, the 'click' in safety locks, and the smooth action in retractable cables.

When selecting a small compression spring for your application, several key factors come into play. These include:

• **Spring Rate:** The spring rate is a measure of how much force is required to compress the spring a certain distance. Choosing the right spring rate is crucial for ensuring proper functionality in your application.

• **Material:** The material of the spring will affect its strength, durability, and corrosion resistance. The choice of material depends on the operating environment and the required load capacity.

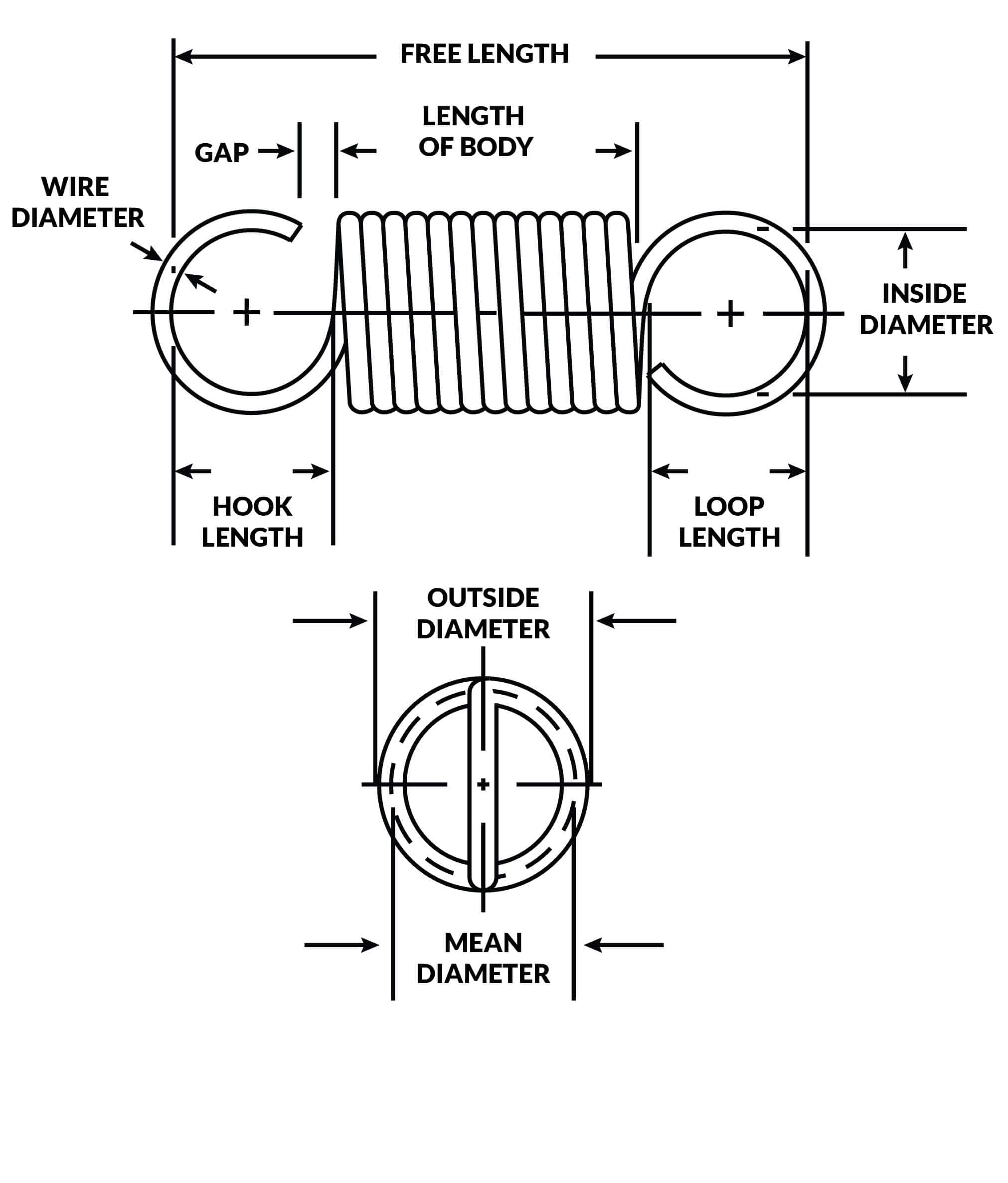

• **Dimensions:** The dimensions of the spring, including its wire diameter, coil diameter, and length, must be carefully considered to ensure a proper fit and function within the intended space.

• **Load Capacity:** The maximum load that the spring can withstand without permanent deformation is an important factor to consider.

• **Corrosion Resistance:** For applications in harsh environments, corrosion resistance is a crucial feature. Springs made of stainless steel or other corrosion-resistant materials are often used in these scenarios.

Selecting the appropriate small compression spring can be a complex process, but it's vital to ensure optimal performance and longevity. Here are some guidelines to assist in your selection:

• **Define the Application:** Start by clearly understanding the intended use of the spring. What forces will it encounter? What environment will it operate in? What is the required lifespan?

• **Determine the Required Force:** Calculate the force that the spring needs to generate to perform its intended function. This will help you determine the appropriate spring rate.

• **Consider the Space Constraints:** Measure the available space for the spring and ensure that the dimensions of the chosen spring are compatible.

• **Consult with a Spring Manufacturer:** Don't hesitate to reach out to a reputable spring manufacturer for guidance. They can help you select the right spring based on your specific needs and provide valuable expertise.

Small compression springs, often overlooked, are crucial components in countless mechanical systems. Their ability to store and release energy, provide support, and absorb shocks makes them indispensable in a wide range of industries. By understanding the key features, applications, and selection considerations, you can harness the power of these tiny powerhouses to create innovative and reliable designs. So next time you encounter a small compression spring, take a moment to appreciate the vital role it plays in our modern world.

From the smallest electronics to the largest machines, small compression springs quietly perform their critical functions, ensuring the smooth operation and longevity of countless systems. They are a testament to the ingenuity of engineering and a reminder that even the smallest components can have a significant impact.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.