Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

The concept of spring compression is fundamental in various engineering fields, from mechanical design to automotive suspension systems. Determining the maximum compression of a spring is crucial for ensuring safe

The concept of spring compression is fundamental in various engineering fields, from mechanical design to automotive suspension systems. Determining the maximum compression of a spring is crucial for ensuring safe and efficient operation. This article delves into the "maximum compression of spring formula," exploring its intricacies, practical applications, and limitations. We'll unravel the factors influencing spring compression, analyze the formula's derivation, and highlight key considerations for optimizing spring performance. Whether you're a seasoned engineer or an inquisitive learner, this comprehensive guide aims to illuminate the world of spring compression.

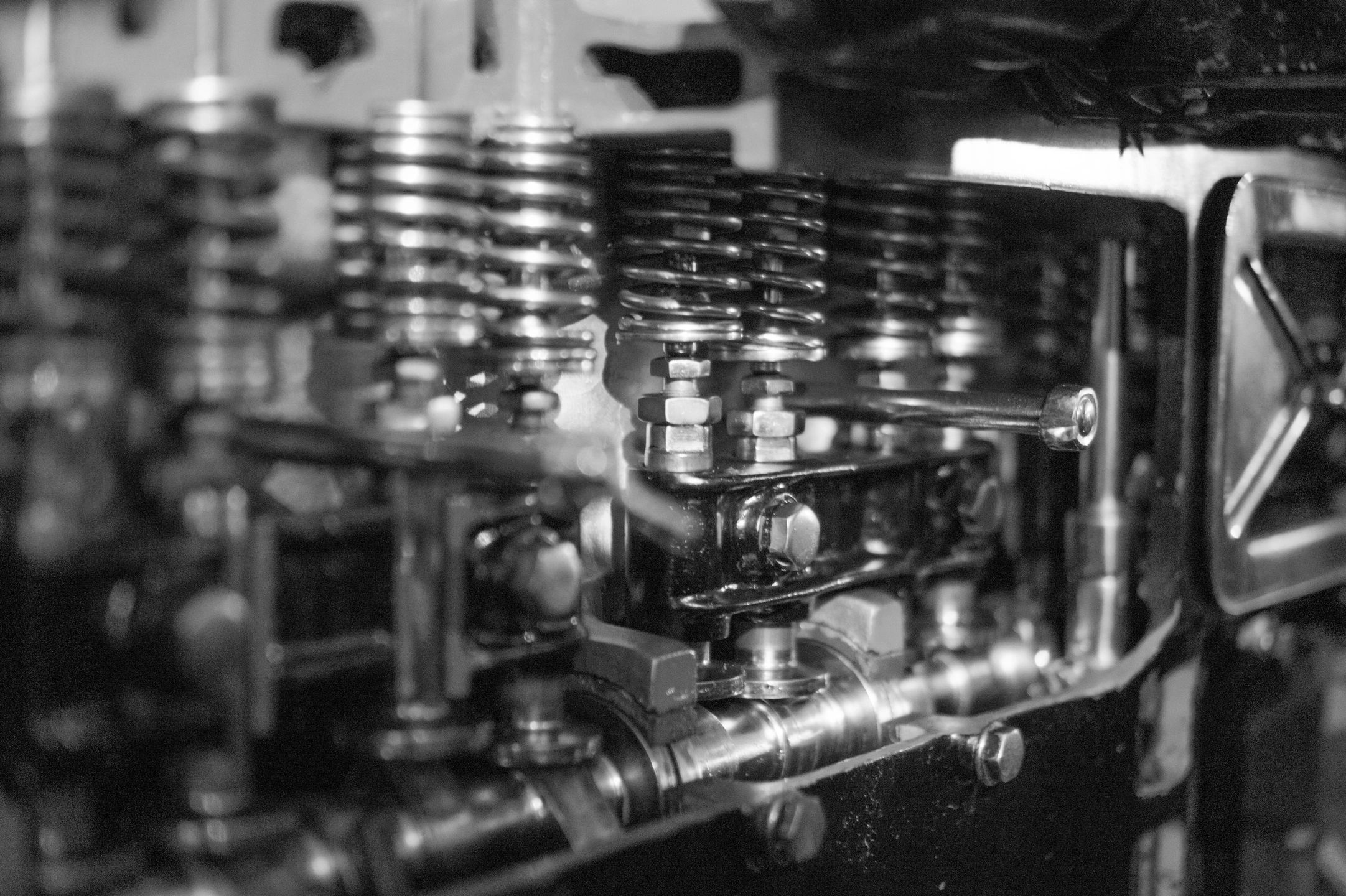

Springs are essential components in numerous mechanical systems, acting as energy storage devices that can absorb and release energy. When a force is applied to a spring, it compresses, storing potential energy. The maximum compression a spring can withstand before reaching its limit is a crucial parameter for engineers to consider.

The maximum compression of a spring is influenced by several factors:

The formula for calculating the maximum compression of a spring is derived from Hooke's Law, which states that the force exerted by a spring is proportional to its displacement from its equilibrium position. The formula is expressed as follows:

Maximum Compression (δ) = F / k

Where:

This formula provides a straightforward way to determine the maximum compression of a spring given its spring constant and the applied force. However, it's essential to note that this formula assumes ideal spring behavior, meaning the spring obeys Hooke's Law linearly throughout its compression range. In reality, springs may exhibit nonlinear behavior, especially at high compression levels.

The concept of maximum compression finds practical application in various engineering disciplines:

To maximize the performance of a spring, engineers need to carefully consider the factors influencing its compression capabilities. Here are some key strategies:

While the maximum compression formula provides a valuable tool for analyzing spring behavior, it's crucial to consider some limitations:

The maximum compression of spring formula is a vital tool for engineers seeking to design and optimize spring-based systems. By understanding the formula's derivation, factors influencing compression, and practical applications, engineers can ensure safe, efficient, and reliable operation of mechanical systems relying on springs. While the formula provides a valuable starting point, it's essential to consider the limitations and real-world factors that may influence spring behavior. This comprehensive understanding will lead to optimal spring design and maximize the potential of these crucial components in a variety of engineering applications.

As we've explored, the "maximum compression of spring formula" is a cornerstone in understanding spring behavior and optimizing their performance. By understanding the formula's intricacies, considering practical applications, and recognizing its limitations, engineers can harness the power of springs for a wide range of applications. Whether you're designing automotive suspension systems, crafting intricate mechanisms, or building resilient structures, a deep understanding of spring compression is essential for achieving excellence in engineering endeavors.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.