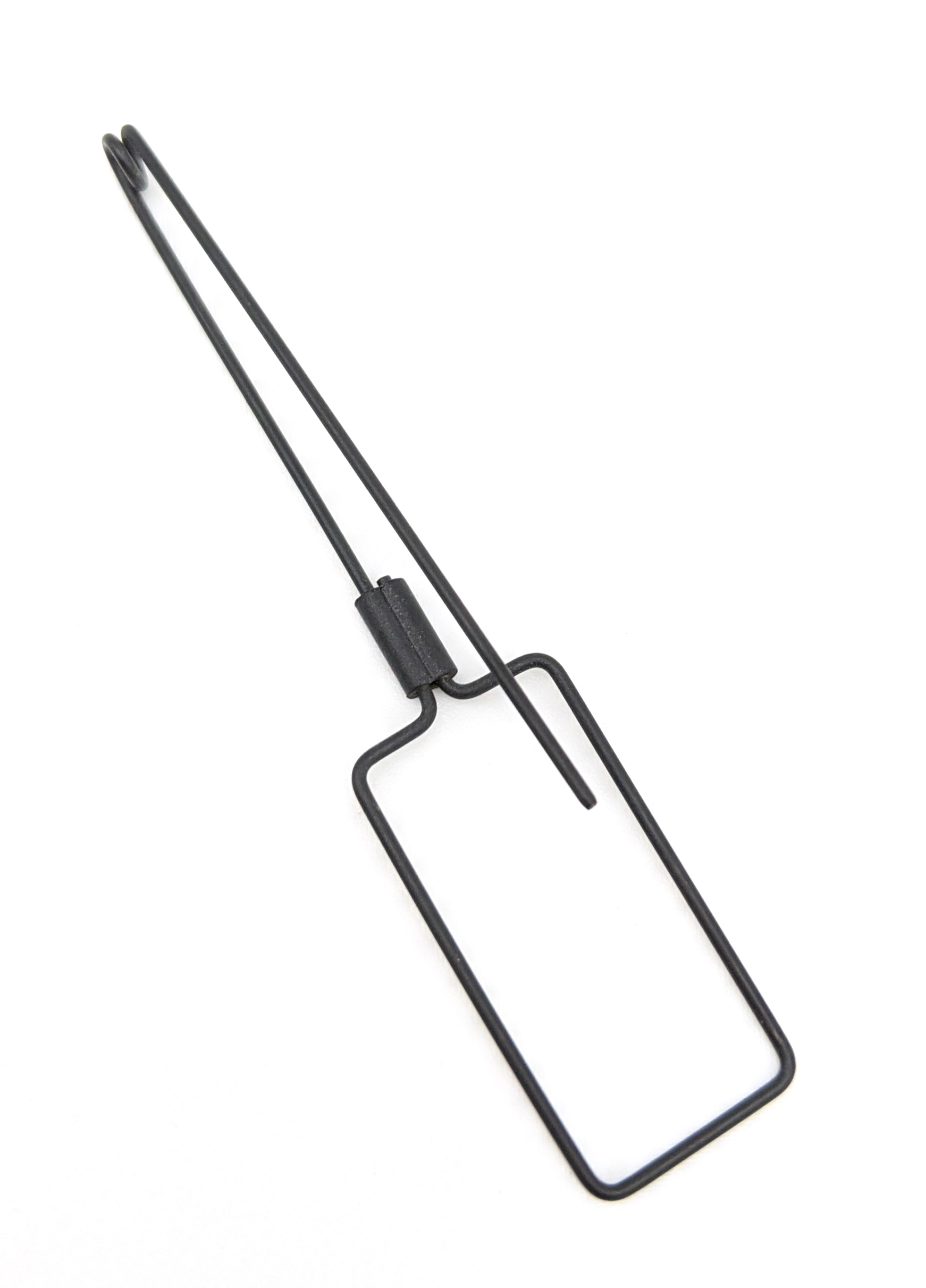

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

We often take for granted the smooth, controlled motion we experience in everyday objects. From car tailgates to office chairs, a hidden force is at work ensuring effortless operation. This

We often take for granted the smooth, controlled motion we experience in everyday objects. From car tailgates to office chairs, a hidden force is at work ensuring effortless operation. This force comes from compression gas springs, compact yet powerful components that are revolutionizing how we interact with the world around us. Let's delve into the world of compression gas springs and explore their functionality, diverse applications, and the advantages they bring to various industries and products.

Imagine a sealed cylinder filled with inert gas, usually nitrogen. Inside this cylinder, a piston rod connected to a piston compresses the gas when force is applied. This compression creates potential energy, ready to be released as a controlled, opposing force. This, in essence, is the operating principle of a compression gas spring. These springs are engineered to provide a predictable and consistent force over their entire stroke, making them ideal for a range of applications.

The versatility of compression gas springs is truly remarkable. They have found their way into a myriad of industries, playing a vital role in ensuring smooth and controlled motion in countless applications. Let's take a look at some prominent examples:

Automotive: Think about the effortless opening of your car's tailgate or hood. That's the magic of compression gas springs at work. These springs provide the necessary lift and support, making these operations a breeze. They are also extensively used in hatchbacks, caravans, and other vehicles, enhancing user experience and functionality.

Furniture: Have you ever adjusted your office chair with ease? It's highly likely that a compression gas spring is responsible for that smooth and adjustable height control. These springs are commonly used in office chairs, adjustable beds, and other furniture pieces, providing optimal support and customizable positioning.

Medical: In the medical field, precision and reliability are paramount. Compression gas springs are employed in hospital beds, operating tables, and other medical equipment, enabling smooth and controlled adjustments that are essential for patient care and comfort.

Industrial: From heavy machinery to manufacturing equipment, compression gas springs play a crucial role in ensuring smooth operation and controlled movement. Their ability to handle high forces and provide consistent performance makes them indispensable in these demanding environments.

The widespread adoption of compression gas springs is a testament to the numerous advantages they offer over traditional mechanical springs. Let's explore some of the key reasons why these springs are becoming increasingly popular:

Controlled, Predictable Force: Unlike traditional springs that exhibit a linear force increase, compression gas springs offer a more controlled and predictable force curve. This makes them ideal for applications where smooth and consistent motion is required throughout the stroke.

Compact Design, High Force: One of the most compelling advantages of compression gas springs is their impressive force-to-size ratio. They can generate significant force within a compact design, making them suitable for applications where space is limited.

Long Lifespan and Low Maintenance: Compression gas springs are known for their durability and longevity. Their sealed design minimizes wear and tear, resulting in a long service life and reduced maintenance requirements.

Versatility and Customization: With a wide range of sizes, force ratings, and stroke lengths available, compression gas springs can be tailored to meet specific application requirements. This versatility makes them a preferred choice for engineers and designers seeking customized solutions.

As technology continues to advance, we can expect further innovation in the field of compression gas springs. Manufacturers are constantly striving to improve performance, increase efficiency, and explore new applications. From advancements in materials and manufacturing processes to the integration of smart technologies, the future of compression gas springs holds immense potential.

In conclusion, compression gas springs are the unsung heroes behind the smooth and effortless motion we experience in a wide array of everyday products. Their ability to deliver controlled force, their compact design, and their versatility make them an indispensable component in various industries. As technology progresses, we can anticipate further innovation in this field, leading to even more sophisticated applications and enhanced user experiences. The next time you encounter a smoothly operating tailgate, an adjustable chair, or a piece of precision medical equipment, remember the silent force of compression gas springs at work, quietly enhancing our lives.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.